The core goal of every asset management strategy is to improve asset efficiency and extend the life cycle to boost output.

But how do you know where to start and how well your program is doing?

The American National Standard Institute (ANSI) has published a set of standards for preventive maintenance you can use to develop your program effectively and ensure you’re getting the most out of your assets.Let’s look a little more at what these standards are and how you can implement them in your organization.

What is the ANSI standard for asset management?

So first we need to clarify a little more what ANSI standards are. Technically speaking, ANSI does not develop its own standards; it provides oversight, approval, and accreditation to the organizations and groups that do develop standards.

Basically, if a company or organization wants to develop a standard or best practice for an industry, they can do it using ANSI’s procedures so that those standards can then become certified standards and recommended best practices for other companies.

For example, the ANSI ISO 550000 standards for asset management were developed by the International Standards Organization (ISO), and ANSI has approved, accredited, and adopted them for use in the U.S.

There’s also the ANSI standard for safety glasses, the Z87.1, which was developed by industry volunteers and then approved by ANSI.

It’s important to keep in mind that standards accredited and recommended by ANSI are just that, recommended. They are voluntary standards that no company is legally required to follow.

However, many of these standards do inform government regulations from OSHA and other regulatory bodies that you are bound by law to follow. That means that even if you don’t adopt ANSI standards, it pays to be aware of them.

What is the purpose of ANSI standards?

ANSI works with industry experts to develop standards so companies can have an industry-specific “gold standard” to help them set internal policies and practices.

For example, you can use ANSI standards such as the TAPPI TIP 0305-34:2008 for maintenance checklists to better define what your preventive maintenance plan and checklists should look like. You can also update them as the standards evolve.

ANSI standards ensure that:

- Assets are evaluated consistently

- Terms and definitions are clarified

- Everyone is safe

One of the most important reasons for having standards in place is for employee safety. The last thing any company wants is for an employee to get injured, and ANSI has published several standards for the industry specifically relating to safety. These are most often the ones adopted by regulatory agencies that require compliance.

What is ISO standard?

ISO standards are internationally recognized procedures and best practices developed by industry experts from around the world.

For asset management, that standard is the ISO 55000. In its most broad sense, this standard provides an overview of asset management, the principles and terminologies, and the expected benefits from adopting the standard.

Within the 55000 standard there are actually three different standards covering specific areas of asset management.

- ISO 55000 covers an overall asset management system within your organization. This would include your company policies, objectives, and process surrounding your asset management goals.

- ISO 55001 goes a bit further to cover how your asset management program is organized, the planning for it, and evaluation of the program, among other things.

- ISO 55002 discusses how to implement your asset management system in line with the other two standards.

What is the difference between ANSI and ISO?

The main difference between the two organizations is that ISO is the group that develops and updates the standards after working with industry experts from around the world.

ANSI evaluates the standards and the processes for developing them and offers accreditation. This is a fancy way of saying that ANSI has its separate group of experts evaluate the standards then offers their stamp of approval so you know that they are standards worth adopting at your company.

What is the difference between ANSI and ASTM?

You’ve probably heard of ASTM International as well. They are another standards organization similar to the ISO.

ASTM typically develops standards more related to materials such as metals and chemicals whereas the standards developed by ISO typically cover more best practices and procedures, but this isn’t true across the board.

Most, if not all of ASTM’s standards are accredited by ANSI as well.

What are the benefits of adopting ANSI standards?

One of the quickest and most impactful benefit you can realize from adopting ANSI standards is a more streamlined and efficient asset management program.

You already know that improving your asset uptime is critical to boosting productivity at your organization. One of the best way to do that is by adopting a robust preventive maintenance program.

You probably have a maintenance system already in place to ensure your assets are running efficiently. ANSI standards help you optimize that maintenance system and identify potential gaps in the program that you may not even know existed.

One of the biggest inefficiencies in maintenance programs is often miscommunication. Many times, maintenance teams are using outdated systems like spreadsheets or even paper to manage their work orders. This can easily lead to incorrect and even missed maintenance work on critical assets, which can bring your assets down at the most inconvenient time.

Problems can quickly arise if everyone on your team is using different nomenclature in their work order details. ANSI standards offer unified terminology, making it easier for everyone on your internal and external maintenance teams to speak the same language.

Inspections are another area that can see vast improvements from adopting ANSI standards, especially if they involve safety or any sort of required government reporting. Inspections are a key component of both safety and maintaining your assets and implementing a standardized methodology for performing inspections prevents you from having retrain people and ensures they are performed the same way every time.

Standardizing your team’s workflows can also have a big impact on your labor costs. Having to independently manage all your technicians leads to more labor costs and more headache. Make sure everyone on your team is using their time effectively by getting them all onto the same basic workflows. That way, when they technician who normally performs that PM is no longer there, anyone on your team can quickly jump in and get the job done.

Another important benefit of adopting industry standards that often goes unmentioned is the impact it will have on your reputation. When someone is looking to purchase a product, whether it’s food or a widget maker, they want to know that they are purchasing a high-quality product.

When your company purchases assets, no doubt the decision-makers spend a lot of time researching different manufacturers to find a high-quality product.

Once you’ve adopted industry standards, you can show your customers that your products are indeed high-quality products because they adhere to accredited, verified, globally accepted standards.

Gaining customers’ trust is one of the most impactful ways to improve your company’s reputation, not to mention your profits.

How can EAM software help with ANSI compliance?

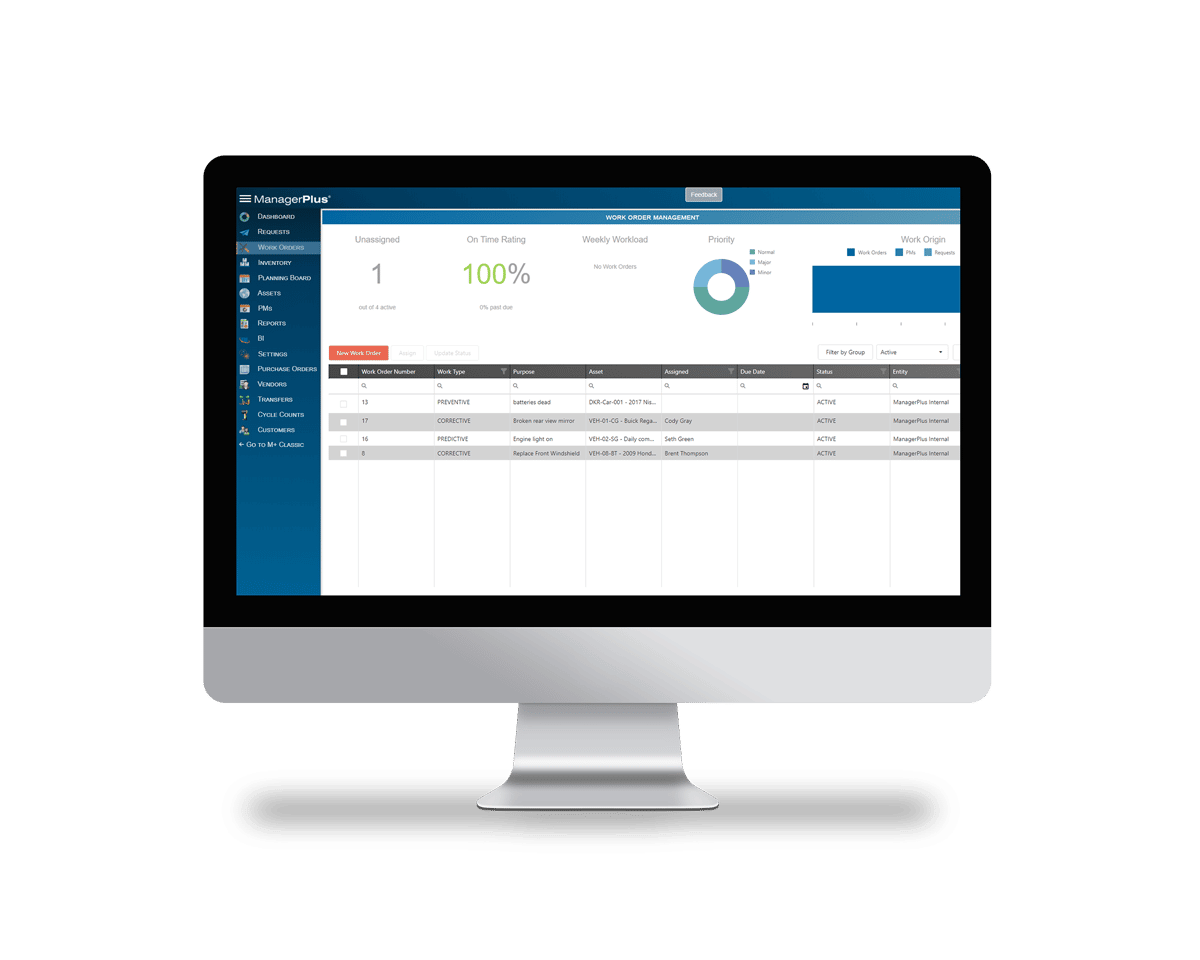

Enterprise Asset Management (EAM) software is a digital platform that stores all your maintenance data in one centralized location and gives you the tools you need to stay on top or you PMs.

Take your work orders, for instance. You have a good idea which of your assets need regular maintenance whether based on run time or condition-based factors. With our Lightning EAM solution, you can have the system automatically trigger a work order to generate for a specific asset when it’s ready for maintenance. You don’t have to do a thing.

The technician receives the work order with all the relevant information already included so they can complete it on time, right within the software. You don’t have to spend any extra time chasing them down to ensure they get it done, and they don’t have to go looking for the information they need. You can even create custom templates for repeated work orders so you don’t have to rebuild them every time.

Almost every company undergoes regular compliance audits and when the time comes, you need to have your inspection reports ready to go. A good EAM solution allows you to standardize your inspections so they are performed accurately every time and stores them all in one, cloud-based database so you can instantly pull them up right when you need them.

To see all the ways that Lightning from ManagerPlus can help you stay in compliance with ANSI standards, schedule a demo today.