While the technology and methods for managing assets may have evolved, the underlying principles of a successful asset maintenance management strategy are still mostly the same.

But to fully understand what a successful asset maintenance management strategy (AMMS) looks like, you need to know the basics of what’s involved.

Asset maintenance management vs. asset management

Before we can look at the benefits of a good AMMS, we need to know the difference between an asset maintenance management strategy and an asset management strategy.

It’s actually fairly straightforward. Asset management involves the entire management system for your assets, from the operators to the technicians and decision-makers, and everyone in between. Every piece of that asset’s life at your company, from the researching and purchasing of the asset, all the way through to its disposal, is part of the entire asset management strategy.

An asset maintenance management strategy is a strategy solely to manage the maintenance activities, costs, parts, etc., for your assets.

An AMMS is a part of your larger asset management strategy.

Why do you need an AMMS?

In the simplest terms, an AMMS is a process developed by your maintenance team to improve the reliability, safety, and longevity of your physical assets.

Developing a good AMMS at your organization can help you:

- Know what assets you have, where they’re located, and their current condition

- Develop a maintenance program designed to optimize and maintain your assets

- Understand the true cost of ownership (TCO) for your assets

- Extend each asset’s useful life

Identify your assets

Identifying your assets may sound elementary, but you may find some surprises. One company that recently implemented our ManagerPlus Lightning enterprise asset management (EAM) software discovered they had undervalued their equipment by as much as 70%.

You can’t properly maintain your assets if you don’t identify them correctly. This involves more than just labeling your truck as a “vehicle.” While it is a vehicle, it’s just as important to determine that asset’s criticality. How vital is it to your production as a whole? How much of an impact would it have on your operation if it were to break down?

This is important because not every asset is maintained the same way. Some assets are more efficiently managed with reactive maintenance while others need preventive maintenance. You need properly identify your assets so you can know what maintenance strategy is appropriate.

Properly identifying your assets also helps you understand the total cost of ownership (TCO) for your assets. If you don’t identify your assets correctly, you may not associate the right costs with them, and you won’t really know if you’re spending your money effectively.

Condition

You can’t properly maintain your assets without identifying and monitoring their condition. As part of developing your AMMS, you need your team to conduct thorough inspections of your assets. This is a good opportunity to establish good inspection workflows between your operators, technicians, and contractors to ensure everyone is on the same page.

It’s a good idea to have your teams assign ratings to your assets based on their condition, their rehabilitation value, and their remaining useful life. These metrics help you evaluate the TCO.

Inspections are an ongoing part of any good maintenance strategy, and you want to store your inspection records in a centralized database that’s easy to access. That way, your technicians can easily pull up the records to reference when repairing an asset and it’s much easier to prove compliance during audits.

Adopting a good EAM software is the best way to manage inspection records.

Maintenance strategy

Once you’ve identified your physical assets and their condition, you can implement the appropriate maintenance strategies.

The primary maintenance strategies are:

- Reactive

- Condition-based

- Preventive

- Predictive

Not every asset needs the same maintenance strategy. Preventive maintenance is the most commonly used and most efficient maintenance strategy, but it doesn’t work for every asset.

Reactive maintenance is sometimes called run-to-failure (RTF) maintenance, but the two aren’t technically the sam. Reactive maintenance involves running an asset until a part of breaks and needs to be repaired while RTF maintenance is letting the asset run until the entire thing fails and needs to be replaced.

The most common example of this is a light bulb. Since you can’t replace parts of a light bulb, the most efficient way to use them is to run them until they break then replace them.

Condition-based maintenance tracks the asset as it operates and repairs or replaces it when it reaches certain pre-determined metrics, such as tires on a truck. When the tread reaches a certain point, or the truck travels a certain number of miles, you replace the tires.

In a nutshell, preventive maintenance involves continuously monitoring your assets using computerized maintenance management software (CMMS) or EAM software and using the software to automatically schedule maintenance activities.

Predictive maintenance is the most cost-intensive strategy, but also the most granular. This strategy involves purchasing sensors and connected technology to collect a stream of data on your assets, which is then evaluated by your EAM software and used to trigger maintenance work orders based on when it predicts that asset might fail.

This strategy is typically only used by organizations with large, complex assets with high criticality.

Optimize costs

Cutting operational costs is often one of the primary tasks for any asset manager and developing a strong AMMS can save you up to 18% a year on maintenance costs.

One of the most immediate ways you can see this is by switching from reactive maintenance to preventive maintenance for your critical assets. A recent report from McKinsey Global Institute predicts that preventive maintenance can save manufacturers anywhere between $200 billion and $600 billion within the next four years.

Aside from the direct savings, you’ll see from your assets running more efficiently with the appropriate maintenance strategy, implementing a robust AMMS will allow you to establish and track new KPIs for your assets. Your EAM software can generate reports for you using business intelligence that will give you a more granular view into exactly where your costs are going and where you can spend your money more effectively.

Get more from your assets

Properly maintained assets last significantly longer than improperly maintained ones. Even with all the modern technology we have to help companies optimize their assets, many organizations still rely solely on reactive maintenance to fix their assets. They simply wait until things break before they repair them.

The myth that this saves more money than implementing a costly AMMS has been disproved for years. In fact, a company that recently implemented ManagerPlus lightning saw a savings of over $600,000 in asset maintenance costs within the first year of their purchase.

With a good AMMS in place backed up by a strong EAM solution, you can get significantly longer useful life out of your assets.

What’s involved in an AMMS?

Ok, so we’ve covered the benefits of an AMMS and why it’s a good idea to implement one at your company. Now let’s talk more specifically about the components of a good AMMS.

- Work planning

- Work order management

- Preventive maintenance optimization

- Resource management

Planning maintenance work effectively

The most efficient maintenance activities are the ones that are planned. One of the main reasons preventive maintenance is so effective is because it’s planned. You know when it’s coming and can prepare for it. You can schedule your technicians so there’s no overlap, and you can order the parts ahead of time so everything is ready when you need it.

Your technicians also perform higher quality work because they aren’t rushing from job to job trying to keep things from falling apart. When they know what’s coming and when they can prepare for the job and get any additional help they might need.

Planning ahead for maintenance work also ensures your crew is safe while on the job and helps you maintain compliance.

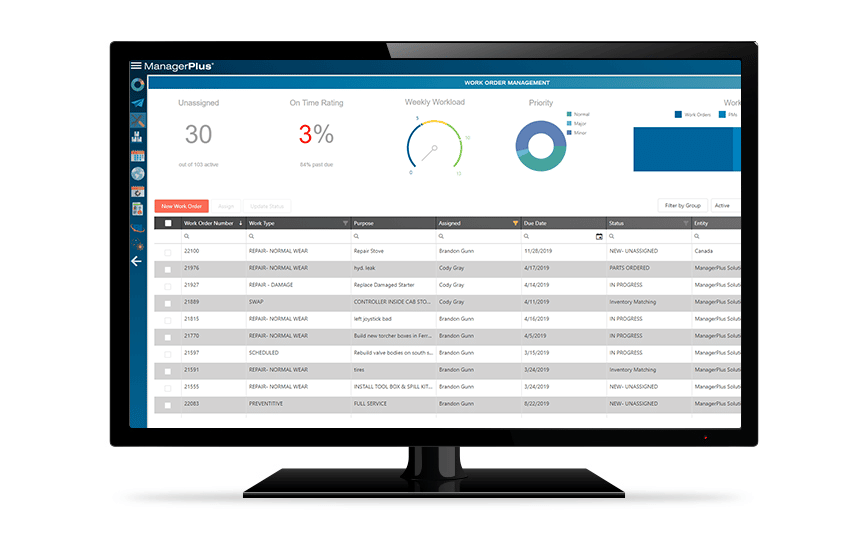

Work order management

Managing work orders efficiently is one of the most vital components of a good AMMS. You need to be able to generate and assign work orders quickly and accurately and modify them when techs need extra information.

You need a system that allows your technicians to access and modify their work orders quickly and easily so everyone on your team can stay on the same page.

Ideally, your AMMS allows you to generate and assign work orders to your vendors easily as well. A good EAM software solution can do this for you automatically so you don’t have to waste time calling and emailing.

Preventive maintenance optimization

While preventive maintenance is designed to help automate and streamline your maintenance operations, it is certainly not a set-and-forget strategy. As you and your technicians begin to use your preventive maintenance strategy, you should continually monitor and adapt it as your organization grows and adapts.

And that’s the beauty of it. A good preventive maintenance strategy supported by a good EAM software allows you to step back from the tedious day-to-day details of your maintenance operations and look at the bigger picture to discover even greater efficiencies in your systems.

Resource management

Maintaining assets always involves having parts and equipment on hand, and if you don’t manage your inventory effectively, the costs can quickly add up. If you are operating solely under a reactive maintenance strategy, you don’t really know what parts to stock until something breaks. In that case, you either have to wait to order parts until you need them which extends your asset’s downtime, or you have to guess at what you’ll need and potentially order and store parts you don’t need.

Identifying your assets properly and implementing the appropriate maintenance helps you identify which items you need to keep in stock.

Optimize your AMMS with ManagerPlus Lightning

The most effective way to implement and optimize an AMMS is with good enterprise asset management software. ManagerPlus Lightning is a cloud-based EAM platform that has all the tools you need to get the most from your assets.

With Lightning you can:

- Track critical asset data

- Manage and store inspection data

- Manage work orders

- Use mobile apps to stay connected anywhere

- Track inventory

- Generate customized cost reports

Track asset data

Lightning keeps a close watch on your assets and gives you critical up-to-the-minute data whenever you need it. It can integrate with connected sensors and technology to gather large amounts of data on your assets and is based in the cloud so your data goes with you wherever you go.

Manage inspections

Inspections are vital to maintaining your assets. You can’t know what to fix if you don’t know what’s broken, but keeping track of your inspections on a spreadsheet or piece of paper is inefficient and creates opportunities for costly mistakes.

Lightning stores all your inspection records in one centralized database that you can access from anywhere, so you don’t have to track down your operators to collect inspection reports. And when it’s time for a compliance audit, you’ve got everything you need, right where you need it.

Manage work orders

With ManagerPlus Lightning, once you’ve set up your preventive maintenance schedules based on your preferred conditions, the software automatically triggers maintenance work when it’s time, sending it to the appropriate technician.

You can even build custom templates for work orders to ensure all the information needed for that task is always included, allowing you to accurately transfer knowledge from your experienced technicians to any new members of the team.

With the Vendor Portal, you can have work orders automatically sent to any third-party contractor you might need to do some work for you. The contractor receives a temporary link with access to only that work order and the relevant information they need. Your system stays safe and secure.

All of your work orders are kept in one place to give you a historical record of how your assets are performing for you. If you start to notice that one asset is requiring a lot more work than expected, you can reevaluate the associated inspections and tasks or decide it’s time to retire the asset.

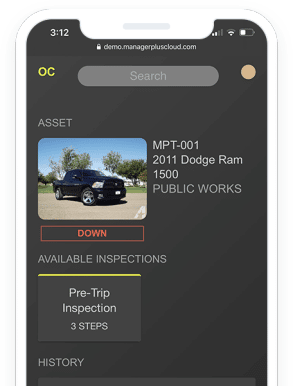

Mobile apps

ManagerPlus Lightning offers two mobile apps as part of our connected ecosystem. The Operator Companion gives your operators the ability to scan a QR code on an asset and quickly perform visual inspections, noting whether an asset needs maintenance with a pass/fail identifier.

The Work Companion app puts all relevant work requests and maintenance information for your assets right in your technician’s hands. By scanning a QR code on the asset, they can instantly open the relevant work order, perform the task, and close it out all from their connected device.

Track inventory

Lightning helps you keep tabs on your inventory so you know exactly when and what parts to order. As your work orders go out, the software can automatically assign parts to them based on how many you have left in stock. It can also tell your technicians where the part is in the warehouse so they don’t waste time hunting it down. When you’re running low, you get a notification letting you know it’s time to reorder.

Intelligent reports

You can only make informed decisions based on the data you have. Our EAM uses business intelligence to generate customized reports on KPIs that you want to track so you can decide best where to invest your money.

Preparation is key. There are a lot of moving parts when implementing an EAM and our expert teams can do the heavy lifting for you. We can customize an implementation package that fits your needs including an on-site audit of your assets and inventory to get them uploaded into the system for you. They work side-by-side with you to ensure everything is set up and ready to go so you can start seeing results immediately.

To get a concrete idea of how ManagerPlus Lightning can help get the most from your assets, schedule a demo today.