Preventive maintenance (PM) is the cornerstone of your asset management program. It’s the key to getting the longest lifecycle out of the equipment, machines, and vehicles that your business counts on.

The best preventive maintenance plans help you streamline tasks and operationalize the workflow in an efficient way. In other words, you shouldn’t spend more time scheduling each maintenance task than actually doing it. But preventive maintenance also goes beyond scheduling to include the business intelligence that leads to a better bottom line.

What is preventive maintenance?

Preventive maintenance is a strategy of maintaining assets proactively to keep them in optimal condition and to reduce the risk of unscheduled repairs and safety concerns. It essentially combats anything that would put production on hold, delay projects, or hurt the company’s reputation.

As part of the larger asset management process, your preventive maintenance plan must include:

- Documented maintenance needs for individual assets

- Schedules of maintenance tasks required before an asset’s performance is compromised

- Cues for teams to begin the preventive maintenance work

- Methods for tracking the status of preventive maintenance tasks through to completion

- An inventory of parts and materials used with each preventive maintenance task

- Documentation of what was done, when, and by whom

What are the benefits of preventive maintenance?

The No. 1 benefit of a well designed preventive maintenance strategy is cost savings. Those savings come from two areas: savings from not having to purchase a new asset to replace an old one; and savings from avoiding asset failures that reduce uptime.

You can quickly calculate the value gained by getting additional life out of an asset. For example, if you can get six year’s use out of a $2,000 piece of equipment instead of just four, you’ve saved $1,000 in replacement costs. If preventive maintenance costs were $200, your net gain is $800.

Avoided failures can be harder to measure—those breakdowns that didn’t happen. But you can probably put a price on downtime for your business. How much revenue would you lose if your business had to shut down for several hours unexpectedly while a critical asset was repaired? What about for a whole day?

Certainly, each asset has several variables to consider beyond just replacement costs and equipment downtime. For example, when it comes to vehicles used in the fleet industry, replacing an older car or truck might yield a greater fuel economy. The variables are endless.

Even so, some estimates place the financial return on investment for PM at 500% or more.

Another clear benefit of preventive maintenance is improved safety. Assets that are in good working order are less likely to create safety risks for workers who use them routinely and for the teams that are responsible for making repairs.

According to the U.S. Bureau of Labor Statistics, there were 199,000 nonfatal injuries in construction and 430,000 in manufacturing in 2018. The National Safety Council notes that 26% of occupational injuries are caused by contact with objects or equipment. Transportation, manufacturing, installation, and construction are four of the top five occupations with a high rate of work-related injuries. Safety is always a priority.

Types of maintenance

Before we dive too far into preventive maintenance, let’s quickly look at two other maintenance strategies.

Reactive maintenance

Reactive maintenance, also known as run-to-failure maintenance, involves letting assets run until they fail, then repairing or replacing them. Many organizations still rely solely on this “if it ain’t broke, don’t fix it” strategy for their maintenance operations believing it’s the most cost-effective way to perform maintenance. Unfortunately, that is far from the truth.

By definition, reactive maintenance means 100% of your equipment downtime is unplanned or unscheduled and a recent study from the Aberdeen research group showed that unplanned downtime can cost an average of $260,000 per hour.

Think about your car; there’s a reason it’s recommended that you change your oil every few thousand miles. If you don’t, the engine will seize and you’ll be forced to replace either the engine or even the entire car. Running your car until it fails is absolutely not the best way to do it.

This doesn’t mean that you should never use reactive maintenance for anything in your organization. In fact, the best maintenance strategies include about 20% of reactive maintenance for assets.

A great example of assets where you should employ reactive maintenance is light bulbs. They are cheap to buy and store and can’t be repaired, so the best option is to just run them until they burn out, then replace them.

Predictive maintenance

If reactive maintenance is about waiting until an asset fails before it’s replaced, predictive maintenance is the other end of the spectrum. Much like preventive maintenance, the goal of predictive maintenance is to anticipate failures and signal repairs before they break.

The way this works is by using sensors and other connected technology, along with enterprise asset management (EAM) software, to monitor your assets in real-time and collect massive amounts of data on their performance. If the sensors detect that certain parts on the asset are beginning to reach a failure point, the software will automatically generate a PM work order and assign it to a technician to begin the repair.

The downside of predictive maintenance is that it requires a large upfront investment in the right equipment to collect the right data. However, it’s also the most cost-effective approach, particularly for companies with several large, complex assets. If you have multiple assets that have a large impact on productivity, any unexpected downtime could dramatically affect your production. In that case, it would be worth the investment to implement predictive maintenance for those assets.

Types of preventive maintenance

When it comes to preventive maintenance, there are many different ways to look at and classify it. Let’s take a look at the three main categories of preventive maintenance.

- Types of preventive maintenance work

- Frequency of preventive maintenance work

- How to classify missed preventive maintenance work

Inspections vs. tasks

There are mainly two types of preventive maintenance jobs that can be assigned to members of your maintenance team. Inspections are pretty straightforward – the operator or technician visually inspects the asset or equipment to determine if there are any repairs or modifications that need to be made.

Inspections can be performed to ensure equipment is running properly, ensure equipment is safe to use, or even to stay in compliance with government regulations. The point of an inspection is to assess equipment and determine what needs to be assigned to a work order.

Tasks are the operations that are performed by the maintenance team in response to an issue discovered during an inspection. These can also be minor repairs made during inspections that don’t require full work orders. For example, if a technician sees that a wire needs a small piece of electrical tape and he happens to have some with him, he can quickly perform the task without submitting a work order.

Time vs. usage

This category refers to when preventive maintenance tasks should be performed or more generally, how to determine when to schedule them.

When you’re evaluating your equipment and looking to develop your preventive maintenance program, you’ll generally want to evaluate the frequency of routine maintenance tasks based on either the time that has passed since the last time the task was performed or based on a certain amount of usage.

The classic example of a usage-based PM is changing the oil on a work truck. Let’s say it’s recommended that you change it every 5,000 miles. It doesn’t matter if you hit that 5,000-mile mark in 3 months or a year. You can expect that the truck will continue to operate as normal as long as you replace the oil at 5,000 miles.

On the other side of that coin are time-based or seasonal PM tasks that are scheduled around certain time frames. Going back to the work truck example, if you’re in a place that has harsher winters, you’ll want to make sure to put your snow tires on before the weather gets bad. For hotels and facilities in warmer climates, you’ll want to inspect the HVAC units before the peak summer season to make sure everything is working properly.

Fixed vs. floating

It’s nearly impossible to achieve a 100% PM compliance rate (the efficiency with which your team completes PM tasks). In fact, the gold standard for PM compliance is 90%, which means that you will have PMs that get missed due to a variety of factors. This isn’t necessarily a bad thing, however, as long as the most critical tasks stay on schedule, you should avoid any major unplanned equipment shutdowns.

When you do have missed PMs that you need to add to your backlog, they can either be fixed or floating tasks which really just pertains to the due date for that particular PM.

For fixed tasks, PMs are generated at fixed intervals, regardless of when the last one was completed. For example, if you have monthly PMs for a particular asset that are generated on the first day of the month, even if the work is completed on the last day of the month, or not at all, a new PM will be generated on the first day of the next month. Fixed tasks don’t account for what should have happened in the past, only what is scheduled to happen in the future.

For a more practical example, let’s go back to the work truck. If you have PMs set to service the truck every 5,000 miles, that means that at every 5,000-mile interval, a work order is automatically generated and assigned. If the technician gets busy or somehow doesn’t service the truck until 6,000 miles, the next PM will still be generated and assigned at 10,000 miles, not 11,000.

Floating PMs are basically the opposite. They are scheduled based on when the previous PM was completed. The timing of these work orders changes or “floats” depending on the date the previously scheduled one was completed. For example, if you have a PM that’s on a 10-day floating schedule, that means that the next PM for that task won’t be generated until 10 days after the previous one was closed out, regardless of when that occurred.

Floating schedules can be useful for non-critical tasks, but the tricky part is that if a work order is left open, the next PM won’t be triggered until it’s closed out. If you decide to use floating schedules for some PMs, you’ll need to stay on top of them to ensure work orders get closed out to keep the schedule moving forward.

How to develop a preventive maintenance plan

No one wants to skimp on maintenance, cutting corners, or deferring upkeep so many times that the potential for asset failure becomes inevitable. However, it’s important to note that too high a frequency of preventive maintenance can also result in excess cost because of the wasted work hours and replacement parts.

A solid preventive maintenance plan must be balanced, taking many variables into account, and must be quantified with data whenever possible.

To develop a preventive maintenance plan, several departments within your organization must evaluate needs and determine priorities. Leadership must be involved to consider the big-picture of the business overall, especially the financial impact of the preventive maintenance plan. Engineering or operations teams must look at the effect preventive maintenance will have on the enterprise, and maintenance teams must consider historical asset performance, manpower, and budgets.

The asset manager should have data that supports the decision-making process, helping the multidisciplinary team judge costs and benefits with some level of detail. Your plan will begin with the goal of maximum uptime, which then can be broken down into smaller, more specific maintenance schedules for each type of asset.

As you create your maintenance schedules, you’ll have some tasks that can be done on certain days, but most will be scheduled more dynamically based on the use of the asset. For example, you might set a goal of removing debris from an injection molding machine at the end of every production cycle, or changing the oil on a vehicle after a certain number of miles on the road.

How to use asset management software for preventive maintenance

Knowing that the goal of preventive maintenance is to thwart potential problems before they arise and minimize the risk of asset failure, you also have the equally important goal of managing the preventive maintenance process effectively and efficiently. While you might be tempted to invest in an application specifically geared towards preventive maintenance, doing so often results in practical limitations.

The more sound advice is to choose a cloud-based, integrated preventive maintenance software platform that handles the full range of asset management responsibilities. By using a comprehensive tool that also allows you to access it from any location, you can streamline preventive maintenance tasks and get a better insight into asset performance across your entire business.

One-off tools simply can’t provide the data points that most businesses need to ensure their assets are optimized. But an integrated platform can.

One-off tools simply can’t provide the data points that most businesses need to ensure their assets are optimized. But an integrated platform can.

With a cloud-based asset management platform, you can collect data that answer key business questions about your preventive maintenance plan:

- What assets do we have, how many, and where are they located?

- How often do we perform PM on each type of asset?

- What triggers PM on each type of asset?

- What maintenance measures have we taken for regulatory compliance or inspections?

- What is our most common maintenance task?

- What parts are we using for PM? Do we have enough? Too much?

- How much manpower is needed for PM?

- Who completed which PM task and when?

- Which assets are going to need replacement in the next 90 days? 6 months?

- How are we predicting our future PM needs?

Your preventive maintenance plan is about more than just scheduling. It’s a strategy that has business implications and a measurable impact on the bottom line.

Of course, you want to revisit your preventive maintenance strategy often—at least once a year, or any time you bring new assets into the fold. You’ll also want to revisit the plan on an ongoing basis with an eye for continuous improvement.

Next steps

A strong preventive maintenance strategy is vital to effectively managing and maintaining your assets, but as with any task, you need the right tools to get the job done right.

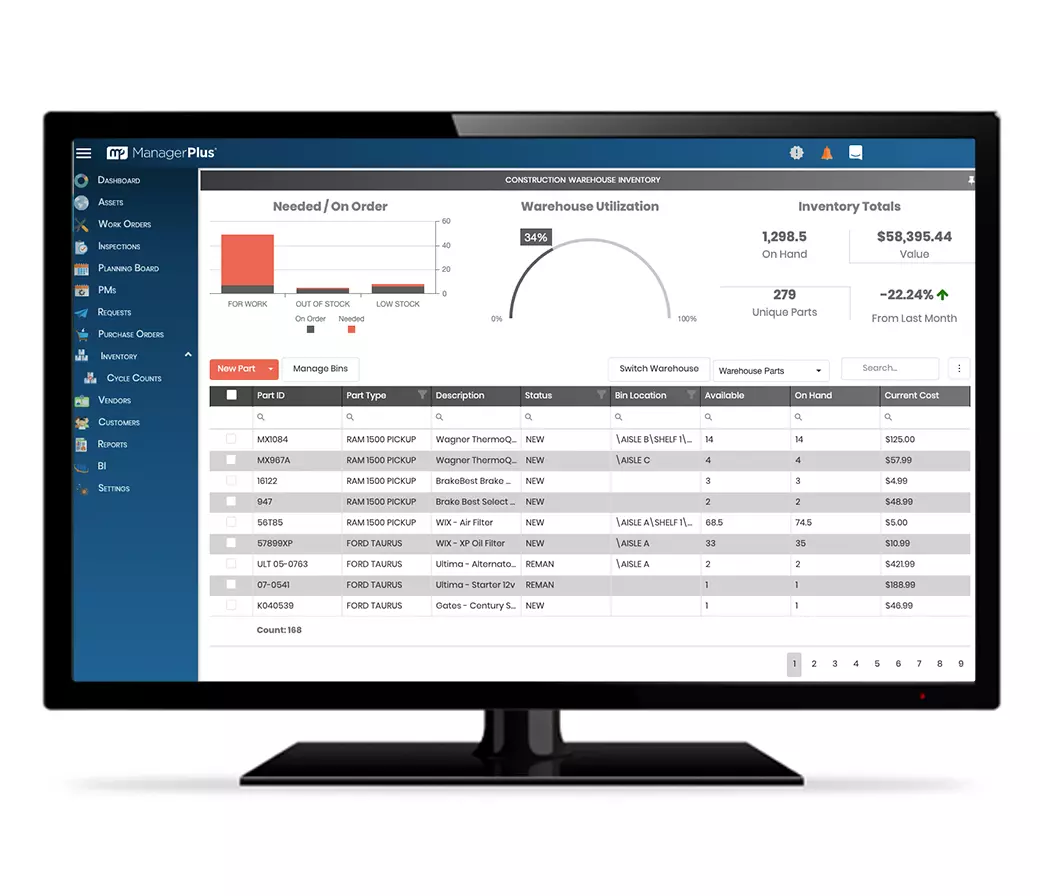

ManagerPlus is a complete, cloud-based EAM solution that has everything you need to develop, implement, and maintain a healthy PM program. The best way to get started is by speaking to one of our experts who can walk you through a live demo of the software so you can see it for yourself.

Executive summary

Preventive maintenance (PM) is almost always the most efficient and cost-effective way to manage and maintain your assets.

The main types of preventive maintenance are:

- Types of preventive maintenance work

- Frequency of preventive maintenance work

- How to classify missed preventive maintenance work

Developing a strong PM strategy for your business involves planning, coordination, and buy-in from your organization but the benefits of it far outweigh the costs. Getting the right EAM software can help you develop and implement a robust PM program and give you data to prove the benefits.