Are you using your data effectively?

Data is a competitive edge, which means failing to use it effectively puts you behind the competition.

SCADA systems can help you make sure you’re not only collecting the right data on your assets and operations but also help you analyze and use it effectively to improve your productivity and boost ROI.

SCADA systems defined

SCADA stands for supervisory control and data acquisition, and is used to describe a system of hardware and software that helps organizations collect large amounts of data on their systems, operations, and assets and provide control and response for those systems from a remote location.

With SCADA systems, you can monitor and control complex systems in real-time from any access point, eliminating the need for manually monitoring input. That means that even if you have multiple production sites with dozens of complex assets spread out across the country, or even globally, you can monitor them all from one central hub.

What makes SCADA work

SCADA systems work by combining multiple types of hardware and software technology to gather large amounts of data and allow real-time monitoring, reporting, and control of your systems, processes, and assets.

A good way to think of SCADA systems is as a link between your assets and your operators and maintenance teams. With a SCADA system in place, your operators can keep track of your assets and production systems in real-time and quickly respond and make necessary changes.

It also makes it easy to implement and operate a predictive maintenance program by instantly notifying your maintenance teams of potential issues that can be fixed before they cause your equipment to fail.

Components of a SCADA system

All SCADA systems have a few basic components necessary to make them work:

- Sensors

- Programmable logic controllers (PLC) and remote terminal units (RTU)

- Human-machine interface (HMI)

Sensors

The first part of any SCADA system is the data. This is collected by sensors attached to your assets and equipment at various stages of the production process. These sensors can be something as simple as an on/off switch to something as complex as pressure sensors, temperature meters, or anything else that can collect data.

Data from your assets can also be input manually from your operators and technicians, particularly from your more senior technicians who know and understand your assets better than most.

PLCs and RTUs

PLCs and RTUs are essentially very basic computers that interpret the data from the sensors, then convert that information into data that can be read by the SCADA software. These computers can communicate with a wide variety of sensors and assets to ensure your system is collecting and analyzing the data correctly to tell you what you need to know.

HMI

Despite its technical and robotic-sounding name, the HMI is simply the main command module that the system operators use to interact with the system. It is the computer that the human operators use to monitor the system and respond when necessary. This allows for one operator to interact with the entire system.

Benefits of SCADA

SCADA systems can have significant impacts on a variety of aspects within your organization. Some of the ways SCADA systems can help you include:

- Improved production quality

- Quick response to system failures

- Reduced equipment downtime

Improve production quality

By design, SCADA systems are collecting vast amounts of data in real-time so you can know immediately if something is wrong. For example, during a production run, you may start to notice that a higher number of items are failing quality inspections. You can quickly analyze the system and determine which machine or process in the system is malfunctioning and make corrections to avoid losing an entire batch.

Respond quickly to failures

Many industries that use SCADA systems deal with highly sensitive products or environments where equipment failures can have catastrophic consequences. A good example is oil and gas pipelines. A minor malfunction in a pipeline can quickly cause a catastrophic spill or explosion so they use SCADA systems to instantly detect and respond to incidents before they become failures.

Reduce unplanned equipment downtime

Unplanned downtime is often one of the largest costs for organizations and SCADA systems coupled with enterprise asset management (EAM) software can help you significantly reduce unplanned downtime. With so many sensors gathering up-to-the-minute data on your assets, you can much more easily predict when equipment failures might happen and take proactive measures to prevent them.

For example, if you know from either the manufacturer recommendations or the experience of your senior technicians when you need to replace a gear on your machine press, your SCADA system can monitor the equipment and tell your EAM software when it’s time to perform the repair, and automatically generate and assign a work order to your technician to get it done.

Who uses SCADA?

Due to the immense value offered by SCADA systems to help organizations improve their reliability and productivity, they are used by a wide range of industries around the world. They are best suited for industries with several complex assets and systems in place or companies with sensitive systems such as food production and energy companies.

Common examples of companies that employ SCADA systems include:

- Petrochemical

- Food and beverage

- Manufacturing

- Transportation

- Water and wastewater

Almost every major system across society that involves complex or sensitive operations uses SCADA systems. Everything from the refrigeration systems in grocery stores to keeping track of energy use in your home, SCADA systems help companies all over the world gather, analyze, and interpret vast amounts of data to make informed decisions.

SCADA and maintenance and reliability

One of the biggest benefits of SCADA systems is how they can improve your maintenance and reliability programs. SCADA systems, while complex, are flexible and scalable so they can accommodate a variety of sizes and complexities of operations. This makes developing and implementing robust reliability centered maintenance (RCM) and preventive maintenance (PM) programs much easier.

Let’s look at a few examples.

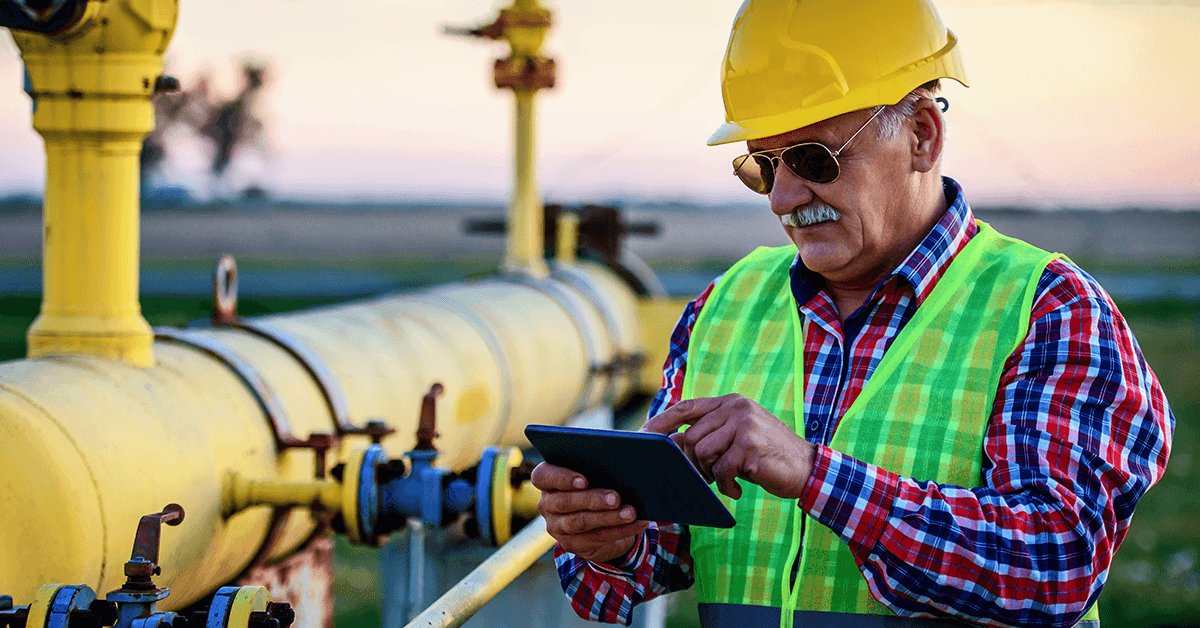

Monitor sensitive assets

In today’s technologically advanced world, many organizations often have highly sensitive assets and materials they deal with on a regular basis. Again, oil and gas pipelines are a prime example. They transport massive amounts of hazardous liquids hundreds of miles along highly pressurized pipelines. In order to prevent potentially catastrophic circumstances and to respond quickly in an emergency, these companies employ SCADA systems for real-time monitoring of every inch of their pipelines.

The same situation applies to IT and telecom companies as well. They often manage thousands of servers and equipment with highly sensitive customer information housed on them that needs to be monitored around-the-clock the protect against unexpected instructions and failures.

SCADA systems can be configured to serve the needs of both these vastly different, yet highly complex industries.

Prevent equipment failures

Preventive unscheduled downtime is one of the key components of preventive maintenance. The idea is instead of waiting for the equipment to fail before your repair it, you identify potential failures and make necessary repairs before that happens. For example, if you manage a fleet of trucks, you know that waiting until the engine seizes to replace the oil is an extremely expensive way to maintain your vehicles.

You know you need to change the oil every few thousand miles, so you can have your SCADA system monitor your vehicles in real-time and tell your EAM software when it’s time for an oil change and automatically generate and assign a work order. This keeps your fleet operating smoothly while saving you money.

Plan investments wisely

SCADA systems also help you make more informed spending decisions regarding your assets. As the system collects more data over time, you can compare that data historically to see how your assets are performing and know when it’s time to repair or replace your equipment.

If you purchase an asset with a useful life of 10 years, as you approach the recommended end-of-life, you can evaluate its performance over time. You might discover that your preventive maintenance program has been effective enough that you can in fact get several more years out of the asset without needing to replace it. Or, based on your cost analysis reports, you may learn that replacing it now is the more cost-effective solution.

Either way, you won’t be able to make the most informed decision without the data collected from your SCADA system.

Next steps

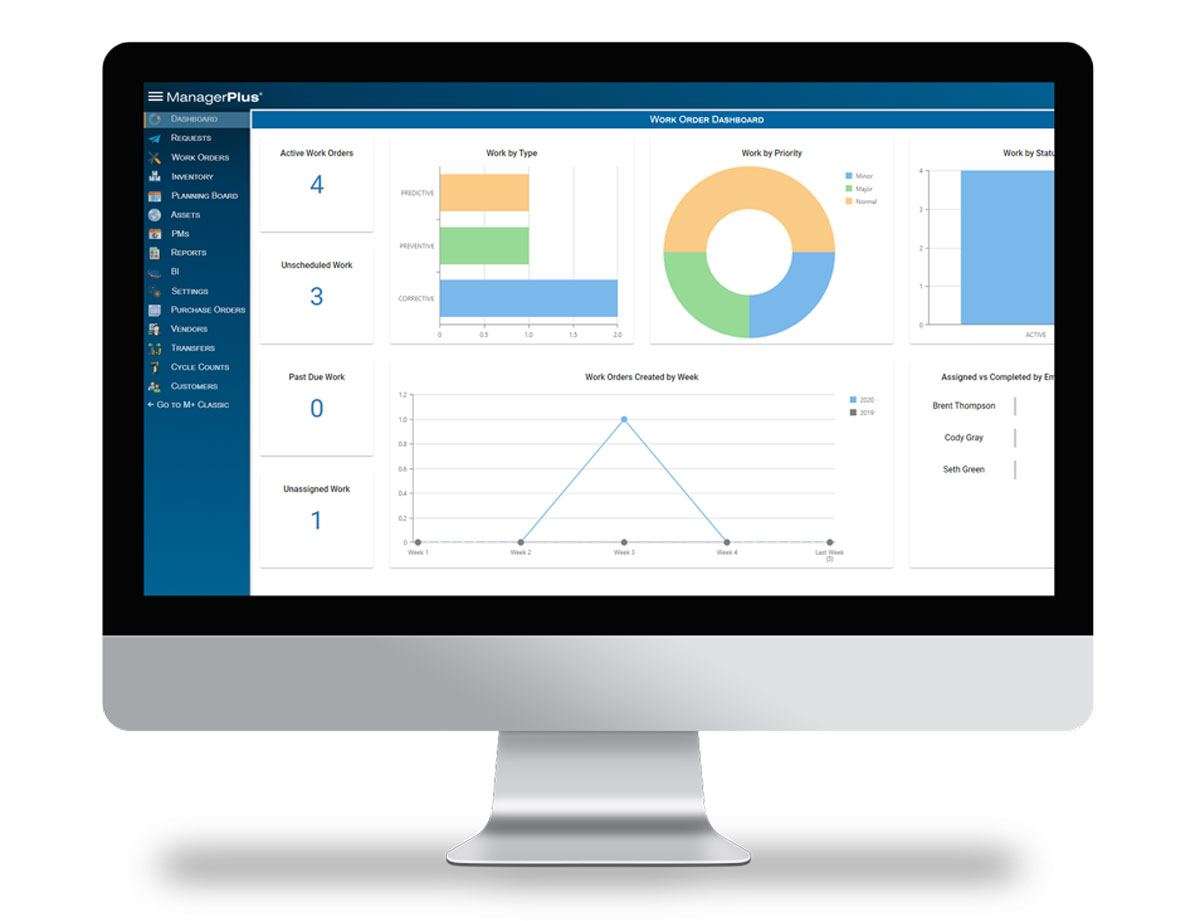

Despite all the benefits of integrating SCADA systems with EAM software, many companies still operate them separately. The best way to get started with the process is by talking to the experts. Scheduled a personalized, one-on-one conversation with our team where you can learn more about SCADA systems and how to get take full advantage of them by incorporating them into ManagerPlus.

Executive summary

SCADA systems combine highly advanced hardware and software that help organizations collect massive amounts of real-time data on their assets and make immediate corrections to equipment or processes if needed. SCADA is used by organizations in a wide range of industries from energy to foodservice and management to water utilities.

Some of the benefits of SCADA systems include:

- Improved production quality

- Quick response to system failures

- Reduced equipment downtime

The most effective way to take full advantage of a SCADA system is to integrate it into an enterprise asset management (EAM) software like ManagerPlus. Schedule a personal, one-on-one conversation with one of our experts to learn more about how you can use EAM software to maximize your SCADA system.