Fleet management continues to evolve as the industry moves away from paper and spreadsheet tracking toward modern fleet management platforms that help you capture clean data for business intelligence.

But even as the industry embraces new technologies, many of the earliest, underlying principles of fleet management still shape industry trends today.

What are fleet management fundamentals?

There are many different aspects of managing a fleet successfully, from researching and purchasing vehicles to maintaining regulatory compliance and maintenance and resale. Underlying this always-changing landscape are three key principles:

- Safety

- Reliability

- Cost management

Safety

Safety is one of the most important aspects of any job, and as a fleet manager, you play a critical role in keeping your drivers safe. One of the best ways to do that is by keeping your vehicles well maintained. A comprehensive preventive maintenance (PM) program is the most efficient and cost-effective way to maintain your vehicles. A properly maintained vehicle will have fewer unexpected failures which keeps both your own drivers and others safe out on the road.

Part of safety is also mitigating risk, which is one reason regulations exist. Your own company likely has several best practices and internal checklists to follow when operating vehicles, but government agencies also require fleet vehicles to comply with many regulations, all designed to mitigate physical and financial risk to drivers and companies.

Documenting your compliance with these regulations helps you avoid fines or shutdowns after an incident, and providing guidelines on what to do after a roadside breakdown or collision will help drivers handle these kinds of stressful situations without putting themselves in danger.

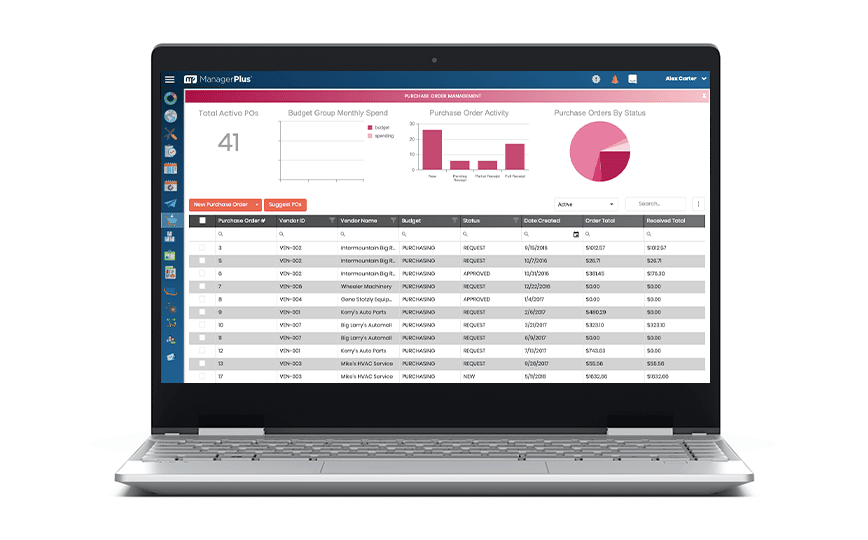

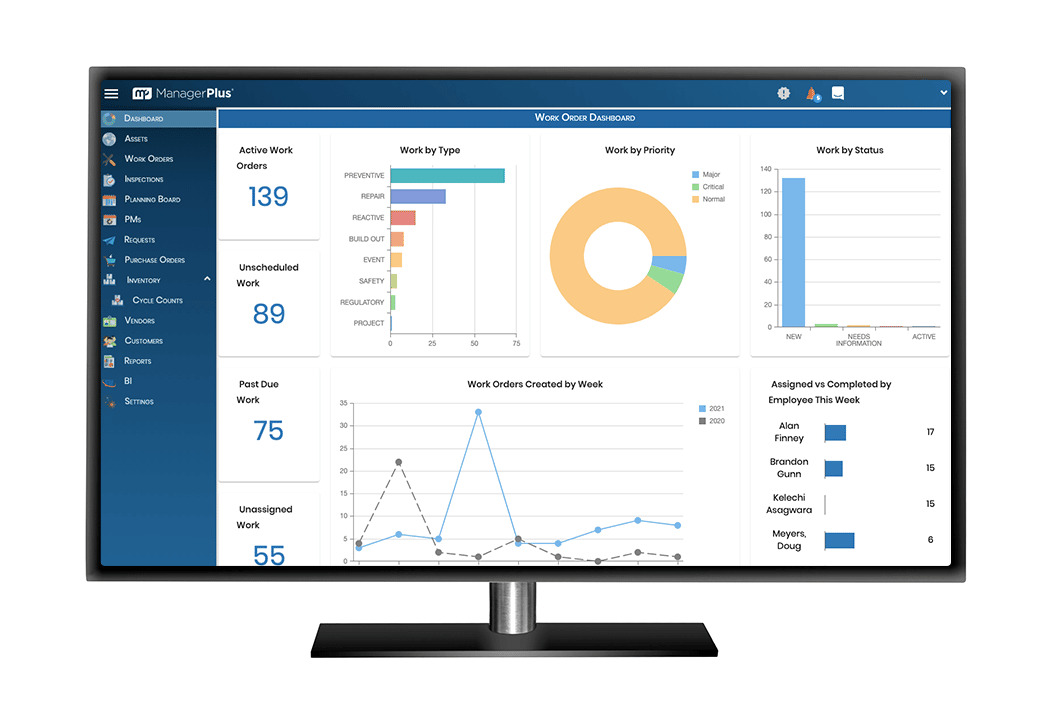

To keep track of all these things while keeping your budgets in check, most fleet managers use fleet tracking software as part of an enterprise asset management (EAM) solution. EAM software is a centralized, always connected database that lets you track everything you need to know about your vehicles, including maintenance and inspection reports, so you always have all the information you need to keep your drivers safe.

Reliability

Reliability is crucial for fleet companies because customers are counting on you to show up and make deliveries on time. Every minute of vehicle downtime not only costs money but also eats away at your reputation in the industry, so it’s important to implement a fleet management strategy that emphasizes dependability.

There are two high-level ways to improve a fleet’s reliability.

Much like a good PM program is a good way to keep your vehicles safe, it’s also one of the most proven ways to improve reliability. Strategically planning your maintenance priorities and scheduling them appropriately allows you to fix small problems before they become big ones, which keeps your fleet vehicles reliably on the road.

Improving your fleet’s reliability also involves making sure you aren’t running vehicles past their useful life. Every asset reaches a point where downtime and maintenance costs exceed the cost of replacing it. Calculating the total cost of ownership (TCO) for your vehicles is how you can determine when the best time is to replace them.

Good EAM software is a great tool for developing and implementing a strong PM program and for tracking your asset’s life cycle. Most EAM solutions enable you to schedule preventive maintenance tasks well in advance to keep your assets running and generate cost analysis reports that break down the costs over the life of your asset so you know exactly how your budget is being spent, and the moment when maintenance costs outweigh replacement costs.

Cost management

As a fleet maintenance manager, you not only have to keep your vehicles safe and reliable, you have to do it all on a tight budget. You need to be able to accurately track all the costs associated with your vehicles and their maintenance activities to know exactly how your budget is being spent, and where you can stretch it further.

There are quite a few costs to consider when managing a fleet, so it’s easy to get overwhelmed or unintentionally fail to account for some. Acquisition costs, ongoing financing, and detailed leasing agreements are all part of a fleet’s budget that need to be taken into account. If you operate specialized vehicles, there are likely several additional costs to consider. You also need to keep in mind the day-to-day operating expenses such as fuel, insurance, and repairs.

Trying to keep track of all these things with spreadsheets or other outdated methods is not only inefficient, you’re also most likely collecting inaccurate data or even missing important data altogether.

When data entry is all manual, there are too many chances for someone to punch the wrong number into the wrong spot, spoiling your data down the line. Remember, at some level, you need to know the last time techs changed the oil on a specific vehicle. But to get the most of from that data, you use it as part of larger calculation for averages and insights into your operations. A bit of bad data can spoil your business intelligence.

With fleet management software, you can keep track of all your asset costs from cradle to grave and get a more accurate picture of how much return you’re getting on your investment. Plus, you’ll be able to make informed decisions based on the right data.

What are fleet management industry trends in 2022?

Fleet management success is a moving target, and these days managers are being asked to take on increasing levels of responsibility. Beyond simply managing maintenance schedules, you’re also now responsible for cost tracking, improving reliability, and providing information for purchasing decisions, among other things.

Thankfully, technology is advancing as well and now provides the tools you need to stay on top of everything.

Let’s look at some of the biggest changes happening in the industry and how they are going to impact fleet managers over the next several years.

Why is data so important?

It’s not just important. Data is king. With the advent and rise of smartphones and connected technology, data has become the backbone of almost every industry around the world. Collecting and analyzing data is a key factor in successfully managing a fleet.

The Internet of Things (IoT) has given us tools to gather data on every aspect of our vehicles, including their location, in real-time. By leveraging this vast amount of data, you can optimize your operations and make cost-effective decisions that positively impact your company.

The problem is, this data isn’t very helpful if it’s scattered across different systems and you constantly have to jump between them and do your best to compare the data. Unifying your data into one, centralized, always connected fleet management software that incorporates data from all your different tracking systems is by far the best way to make effective use of your data.

The you can see the exact same problem at some organizations when information is siloed between departments. Companies are successful when there is a free and reliable flow of information between design, production, sales, and logistics. As soon as one department is out of the loop, things stop working.

How can you make the move to more remote work?

How can you make the move to more remote work?

Even as the unprecedented events of 2020 begin to wind down and workplaces begin to adopt some sense of normalcy again, many companies will continue to rely on remote fleet management. The only way to make this work is to have real-time visibility into your fleet operations.

The biggest challenges to managing fleets remotely are retaining visibility into your vehicles and staying in touch with your team. Modern fleet management software helps you solve both of these problems by keeping you always connected to your assets and your team.

Mobile-friendly software and smartphone apps allow you to communicate and update your data in real-time from wherever you or your team happen to be. You no longer have to be physically on the job site to be able to track your vehicle maintenance.

Even as budgets tighten in response to recent economic conditions, the value of fleet management software continues to prove itself in a remote environment.

What are the new roles of connected technology?

A trend on the rise throughout the fleet industry is the use of tracking systems and telematics, which are poised to become a $75 billion industry by 2025. Besides pinpointing an asset’s location, these systems also collect vast amounts of vehicle and routing data.

For instance, GPS systems can map driving routes and monitor idle time. This functionality makes it possible for a fleet manager to see what’s happening in the field, and then use that information to create more efficient routes. Month-over-month, improvements in driving time and fuel consumption across an entire fleet will lead to savings.

In addition to improving efficiency, tracking systems also protect assets. Remote authorization settings allow a manager to watch over and protect a vehicle and its cargo. And, if an asset is stolen, the company can share location information with law enforcement to assist with recovery.

Meanwhile, U.S. safety regulations mandate fleet tracking using electronic logging devices (ELDs). ELDs are becoming compulsory for proving compliance with rules that govern operators’ on-hours and required rest periods.

Using fleet management software, you can collect all the different data in one place and quickly analyze it to spot inefficiencies and potential improvement in your operations. The increasing adoption of 5G technology will only improve the value of this software as mobile-friendly software and connected apps will get much faster and be able to handle exponentially larger amounts of data.

It won’t be long before the industry is able to take advantage of its data in entirely new ways.

How does all this affect budgets?

The American Transportation Research Institute found the average marginal cost per mile incurred by motor carriers recently increased 7.7%. Costs rose in just about every category (except tires), with fuel costs showing the highest year-over-year growth of 17.7%.

Budgets will continue to be stretched even further going forward, so when it comes to improvements and upgrades, decision-makers might be more inclined to “save money now” instead of investing in newer assets with a longer-term payoff.

And as a fleet manager, it’s your job to make the business case for every asset investment, while always keeping the big picture in mind. In a season of tight budgets, it’s helpful to turn to data collection and analysis to find clever ways to stretch your fleet budget.

Life cycle costs are one fleet maintenance metric to monitor. Calculating the life cycle cost of a vehicle is more than just subtracting the resale value from the vehicle’s purchase price. It encompasses the operating, maintenance, insurance, and registration costs over the entire duration of a vehicle’s ownership. Ideally, a manager should replace an asset before the maintenance and downtime costs overtake the value the asset provides, information you can use your fleet management software to help you find.

You’ll also need to start using data to make smarter purchasing decisions. It’s not uncommon for fleet managers to just look for the “best deal,” but investing in a vehicle with a lower TCO is almost always the better option. It may not be the absolute cheapest you can find, but your EAM software can help you prove it will save you money in the long run.

Another impactful way to cut costs is by improving the productivity of your maintenance team. Assigning tasks to the right technicians with the right skills, streamlining work orders, and using mobile applications to speed up data collection are all areas that can be improved upon if you have the right tools.

It’s often possible to streamline your PM operations as well by, among other things, automatically scheduling routine tasks, tracking your inventory levels, and generating reports on your target KPIs.

With the right EAM software, you can likely discover many ways to cut costs and improve your ROI across your fleet management operations.

Where can you start to set your own trends?

Modern fleet management involves everything from acquisition to compliance reporting to preventive maintenance. Today’s industry is clearly trending toward technology and harnessing the power of data, while always striving to get the most out of every penny in your budget.

Vehicle maintenance software provides the foundation you need to meet the challenges of today and realize the potential of tomorrow.

Find out what advanced maintenance management software features can do for your fleet management operations. Request a personalized demo of ManagerPlus Lightning today.

Did I miss anything?

The fleet management industry is always evolving but three underlying principles still remain safety, reliability, and cost management.

As the industry continues to evolve and adapt to a changing world, there are a few important trends to pay attention to:

- Importance of data

- Adapting to remote work

- Connected technology

- Stretching budgets by doing more with less

Fleet management software can help you keep up with these trends and get the most ROI from your vehicles. Get a live demo of ManagerPlus Lightning today and start optimizing your fleet management operations.