It’s hard to know how you can make things better if you don’t have a goal, which is why every successful organization uses key performance indicators (KPIs) to track and measure success.

Developing KPIs for you fleet maintenance and management operations is one of the best ways to improve your productivity and keep your costs under control, and fleet management software helps you do that.

While things like cost per mile and fuel expenses are good metrics to track, they aren’t really good KPIs.

Let’s look at some indicators that are good for helping fleet maintenance teams get the most out of their vehicles.

What are fleet management KPIs?

Fleet management KPIs are essentially benchmarks that you can use to determine the effectiveness of your fleet management operations. Once you’ve established them, you can quickly begin to spot inefficiencies and gaps in your organization you can fix to reduce your costs and improve the effectiveness and productivity of your fleet.

Some of the main goals for developing KPIs for your fleet are to help you:

- Boost efficiency

- Improve productivity

- Control costs

You can think of the goals as destinations, while the KPIs are like the GPS unit that tells you where you are in relation to where you want to be.

How should you develop KPIs for your fleet?

Before you can begin developing your KPIs, you need to know what you’re looking to improve. But it’s hard to know what goals you need to aim for if you don’t know where your inefficiencies are.

Start with asking some basic questions, including :

- Are you looking to cut downtime for your vehicles?

- Are you spending too much money on repair costs for your fleet?

- Are you having trouble keeping the right parts in inventory?

Answers to questions like these can help you get an idea of some specific areas where you should be developing benchmarks.

One way to help answer these questions is to look at whatever historical data you have on your fleet performance, so you can see what areas have room for improvement.

If you don’t have much historical data, or if everything is written down on paper or scattered across spreadsheets within your organization, then you can talk with your team to see if they can shed some light on where you might have gaps in your operations.

Many times KPIs can come from higher up on the food chain as well. Executives and department heads might have specific goals or metrics in mind that they want you to meet. That said, there are two advantages to generating your own KPIs. One, the goals are more likely tied directly to conditions on the ground. And two, you have an opportunity to show your value to the organization.

What are examples of KPIs for fleet management and maintenance?

There’s certainly no shortage of things to keep track of when it comes to managing a fleet, but there are a few general KPIs that repeat across the industry.

As your team is building out the KPIs that you want to track, considering looking at things like:

- Vehicle total cost of ownership (TCO)

- Preventive vs. reactive maintenance

- PM compliance rate

- Downtime prevention

They’re some of the more common ones in fleet, and there are likely good reasons for that. You can save yourself the effort of reinventing the wheel by looking at what others are already doing.

Track the total cost of ownership for your vehicles

When evaluating the cost of their vehicles, most fleet managers don’t consider every possible cost involved. They mostly only look at fuel costs, maintenance costs, and costs per mile. Finding the total cost of ownership for your vehicles is a little more involved, but it’s worth the extra effort.

To get a complete picture of how much your vehicles are costing you, you also need to add in things like the purchase price, the cost of downtime for the vehicle, and replacement cost.

The basic formula for calculating TCO for your vehicles is to add the purchase price, operating costs, and maintenance costs together.

Once you’ve calculated your TCO, you can begin tracking it across your fleet and set a KPI to determine when to continue maintaining your vehicles or replace them.

Find your ratio of preventive vs. reactive maintenance

You probably already know that preventive maintenance is almost always the best way to maintain your assets. With the right preventive maintenance software, you can increase asset uptime and reduce maintenance costs.

A good key performance indicator to track across your fleet maintenance operations is the ratio between the amount of preventive maintenance to reactive maintenance. The easiest way to track this is by looking at your work order history in your fleet maintenance software or even generating a report from the software to quickly compare the two.

The numbers change across industries, but for many, the gold standard in a 80/20 split. When companies first start tracking this KPI, though, there’s good chance they’re closer to an even 50/50 split between proactive and reactive maintenance.

While you do want the number of PMs to be significantly higher than the reactive work orders, not all reactive maintenance work is bad. In fact, for some assets, it’s the more cost-effective way to manage them.

Ultimately, this KPI is good to track because it can quickly show you how your maintenance operations are affecting your bottom line. Preventive maintenance tasks generally tend to be a lot less expensive than reactive maintenance tasks so the more PMs you do, the more money you save.

Understand your PM compliance rate

Preventive maintenance is really only useful if you complete the work orders on time. The whole point of preventive maintenance is to anticipate equipment failures before they happen and perform work before things break.

The classic example is oil in an engine. PM schedules are put in place to replace the oil and filter before the engine seizes up creating a much more expensive repair. But it’s only effective if you actually replace the oil at the right time. If the task gets skipped and the engine seizes, then the PM was useless.

That’s why tracking your PM compliance rate is a good way to determine the effectiveness of your maintenance operations. PM compliance rate is simply the percentage of your PM work orders that are completed on time.

A low compliance rate is a good indicator that it might be time for some retraining for some of your techs or even that you need to hire additional help.

Or, it could be something else altogether. The point is that your team isn’t completing tasks efficiently, that’s certainly something worth further investigation.

Tracking PM compliance rate can also help you figure out your technician’s productivity rate. As you start to keep a record of your tech’s work order completions, you might find ways to streamline your tech’s workflows and improve productivity.

Keep track of equipment downtime

Downtime is expensive for any organization but if you’re not effectively tracking the amount of downtime you’re experiencing, you can’t know how much it’s costing you.

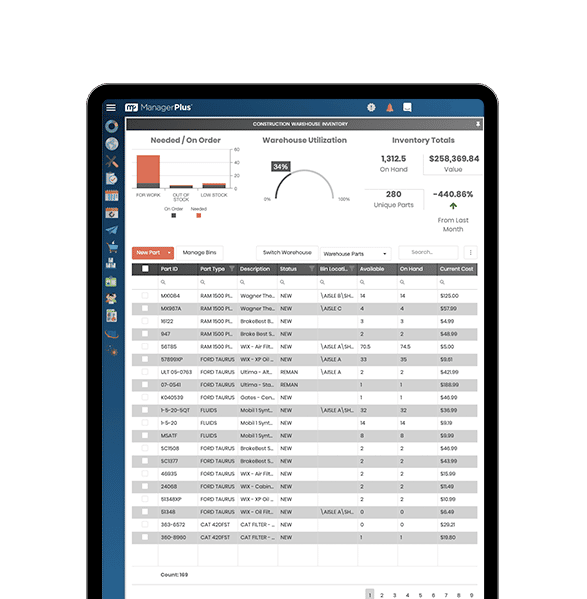

Setting a KPI around the amount of asset downtime you have and using fleet maintenance software to keep track of it over time can help you discover gaps you might have in your maintenance operations. Maybe your team is understaffed or your inventory always arrives late or maybe a certain vehicle is experiencing more downtime than expected and it’s time to replace it.

Whatever the case may be, if you don’t know how your downtime is affecting your organization, you can’t figure out ways to reduce it.

What are examples of KPIs for drivers and truckers?

While the KPIs mentioned above are good ones for managers and supervisors to keep track of, there are some that drivers and operators can help keep track of as well.

Track inspection reports to maintain regulatory compliance

Driver vehicle inspection reports (DVIR) are a part of life for every fleet and by law fleet operators are required to keep track of them in order to pass DOT audits or road checks.

Using fleet management software lets you and your drivers perform and store your DVIRs electronically so you always have them available and can track them over the life of your vehicles and across your entire fleet.

Setting a KPI for your drivers and operators to perform thorough inspections helps you maintain DOT and other regulatory compliance which helps you avoid costly fines and damages to your reputation.

Using cloud-based software, your inspection reports are uploaded instantly, and you can immediately notify and assign techs to address an issue before you fail an audit. If the program has a mobile app as well, then your team can perform inspections and maintenance work all from their connected device, without having to wait for hand-written inspections or work orders.

The most important part is that you can keep track of inspections and maintenance over time so you can develop a key performance indicator for your team to ensure you’re vehicles are always in compliance.

Monitor safety and driver behavior

The most important job of any fleet manager is to keep your drivers, your vehicles, and everyone else on the road safe, and just like you can with costs, expenses, and maintenance, you can track safety.

It’s important to set KPIs around safety that both you and your drivers can get on board with to make sure everyone’s working toward the same goals. When it comes to safety, you can track things like the number of incidents in a given period and then make note of the details and who’s fault it was.

You could also consider establishing some safety training requirements for your drivers and offering extra incentives for them to go above and beyond the standard safety requirements. Setting a KPI for safety and driver behavior is not only important for keeping everyone safe, but it can also help you avoid costly fines and legislation.

How can you optimizing fleet performance with fleet management software?

When setting KPIs, the ultimate goal is to optimize your team’s performance by reducing unnecessary costs and improving the productivity of your fleet. The best way to do that is with data. As with most any problem, you can’t fix it if you don’t know it’s there in the first place. It’s why operators perform inspections on equipment, to detect problems before they become a larger issue.

In the case of your fleet, to optimize your performance and discover areas for improvement, you need a good fleet management software platform that can help you track all the important data for your fleet and help you figure out where the inefficiencies lie.

Fleet management software can help you do things like:

- Automate work orders

- Track and store inspection reports

- Access data from any device

- Generate KPI reports

Automate and track preventive maintenance operations

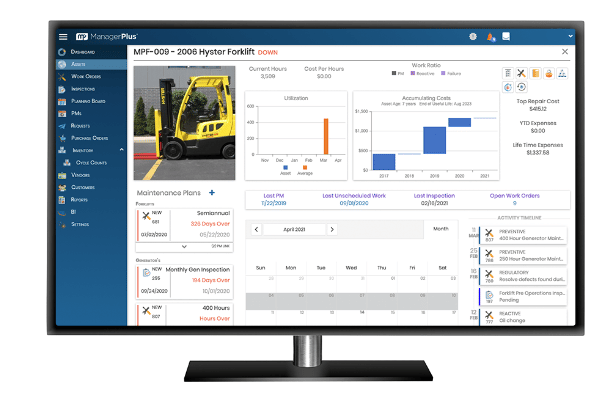

The key to any good preventive maintenance program is being able to anticipate when tasks need to be performed and automate the work order process, so things happen on schedule. With good preventive maintenance software, once you import your asset data, you can set a PM schedule for each asset and automatically generate and assign work orders when it’s time for work to be done.

If you know you need to change the oil every 20,000 miles, you can set the program to generate a work order and notify the right tech at 18,000 miles so you know it gets done when it’s supposed to. And since it’s all based in the cloud, you can track the work orders in real-time and immediately follow up with the techs or answer questions that arise.

In ManagerPlus, you can use the Vendor Portal to set up PM work orders to automatically go to vendors if you need to bring in some outside help.

Best of all, you can track your work orders over time and keep track of the costs associated with them to see if there are places you could be saving money. Keep your entire team up to date on how well you’re meeting your KPIs by automating and tracking your work order processes.

Always have up-to-date inspection reports

Inspections can make or break a fleet operator so you need to have fleet management software that can help you easily perform and store your inspection reports. ManagerPlus lives in the cloud so the moment your drivers upload an inspection report, you can verify it to make sure there aren’t any issues or automatically assign a technician to take a look if need be.

When it’s time for an audit, you’ve got quick access to all your up-to-date inspection reports so you don’t have to worry. And keeping track of all your inspection records over time helps you ensure your team is meeting your KPIs.

Perform tasks and access information from any device

By definition, your team is always on the go so you need fleet management software that your team can take with them. With mobile-friendly software like ManagerPlus, everything is easy to use and accessible from any device. Whether you’re on your laptop, desktop, phone, or tablet, everything you need is right at your fingers.

With the Operator Companion app, your drivers and operators can perform inspections from the palm of their hand with any connected device. Techs can instantly access work orders and relevant information by scanning a QR code (barcode) from their smartphone or tablet through the Work Companion app, then perform the job and close out right in the same app.

Having this data so readily available and accessible helps keep your team on track to meet your KPIs. Since everyone on your team always has access to the most important data, you can communicate seamlessly across your teams so everyone is on the same page and can work together to pick up any slack.

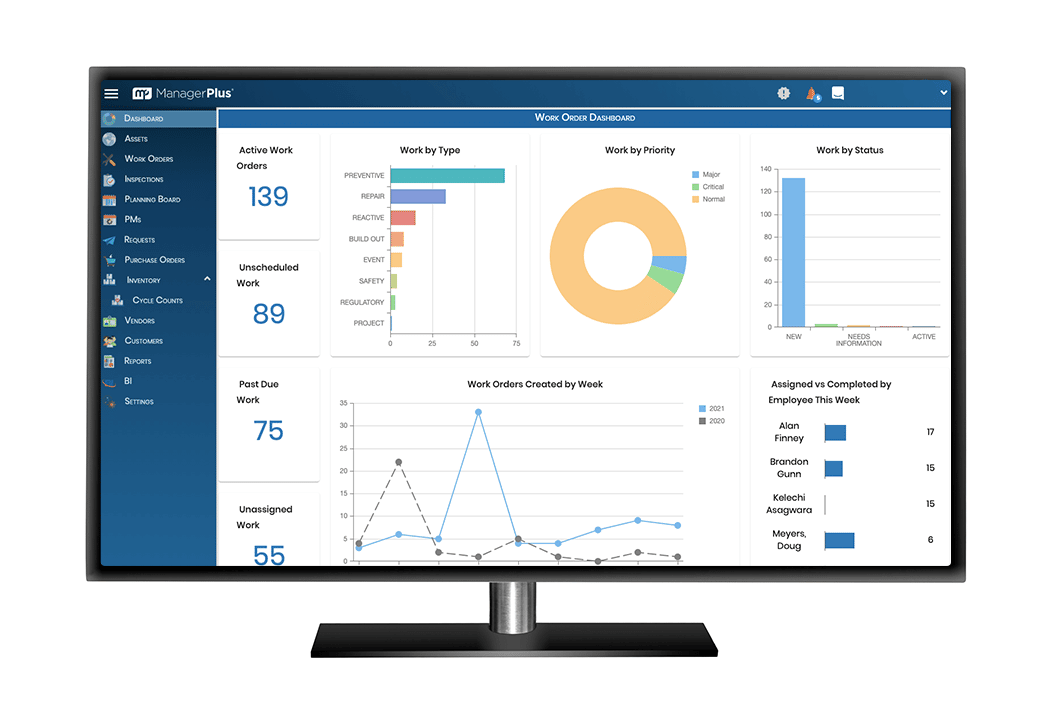

Generate reports to stay up-to-date on your KPIs

One of the most important ways you can use fleet management software to help optimize your operations is by generating customized reports on the KPIs you set for your team. Once you import your data and begin tracking things like your work orders, costs and expenses, inventory, and everything else, you can easily build reports specific to the metrics you want to track.

This makes it easy to spot areas where you might have room for improvement and quickly determine ways to close the gaps. It also helps you better quantify just how much value your team adds to your organization.

Ever feel like you and your team are under-appreciated by the upper management? With these reports in hand, you can prove to the executive team just how much your team impacts the company’s bottom line. You’ll have verifiable data you can use to make better purchasing and investment decisions to make sure you’re getting the most out of your vehicles.

Next steps

If you’re ready to see how fleet management software can help you quickly establish KPIs for your team and optimize your operations, we’re here to help. You can schedule a time to talk with our team of experts at a time that works best for you. They’ll walk you through a live demo and show you just how easy our software is to use.

Get started today.

Executive summary

Nearly every successful organization uses key performance indicators (KPI) to track their progress and measure growth as a team. For fleet operators, things like cost per mile and fuel expenses are certainly important metrics to keep track of, but they don’t really give you a goal to shoot for or a way to measure success.

For fleet managers, consider developing and tracking KPIs around:

- Vehicle total cost of ownership (TCO)

- Preventive vs. reactive maintenance

- PM compliance rate

- Downtime prevention

In order to successfully track these KPIs, it’s helpful to have good fleet maintenance management software in place. ManagerPlus helps you track all the important data you need and generate reports on your specific KPIs so you can see where you are and how to get where you want to be.