Unplanned maintenance work means holding more parts in stock, but 90% of MRO inventory goes unused every year.

ManagerPlus provides a comprehensive and easy to use EAM for streamlining your asset management.

Unplanned downtime can cost an average of $260,000 per hour according to a study by the Aberdeen research group.

A well-managed preventive maintenance strategy is crucial to keeping your assets online longer.

While not every asset needs preventive maintenance, there’s a good chance your most critical ones will. To operate a good preventive maintenance program, you need an always connected, easy-to-use EAM solution like ManagerPlus.

Unplanned maintenance work means holding more parts in stock, but 90% of MRO inventory goes unused every year.

On average, technicians are only on wrench about 25% of the time. Reactive maintenance means wasted maintenance labor costs and more operator downtime.

Reactive maintenance leads to more unplanned downtime which can cost an average of $260,000 per hour.

Many assets are not designed to run to failure and over 90% of equipment failures are due to avoidable maintenance issues.

Scheduled maintenance work means you can know exactly where to set your par levels and only order parts when you need them, not because you got a great deal.

According to the Office of Energy Efficiency and Renewable Energy, preventive maintenance costs, on average, are 27% less than that of reactive maintenance.

Preventive maintenance is a proven strategy for reducing asset downtime. A recent study from the McKinsey Global Institute shows preventive maintenance can reduce downtime by 50%.

According to a report from McKinsey Global Institute on the Internet of Things, preventive maintenance can lead to a savings of anywhere from $200 billion to $600 billion for manufacturers by 2025.

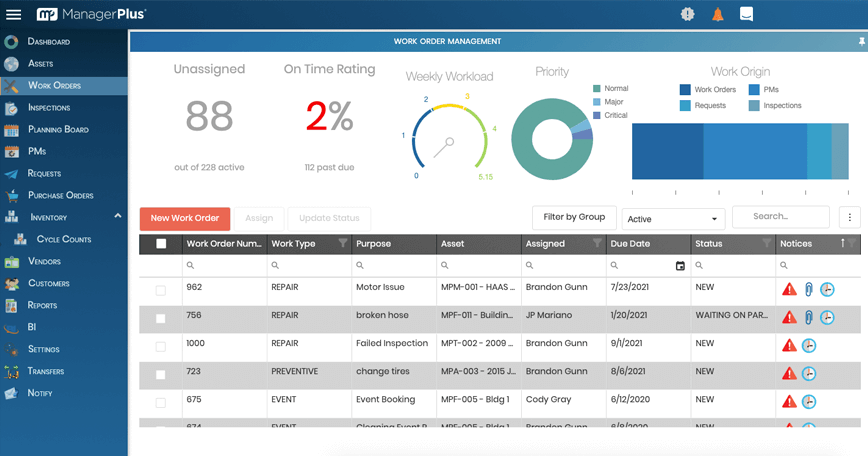

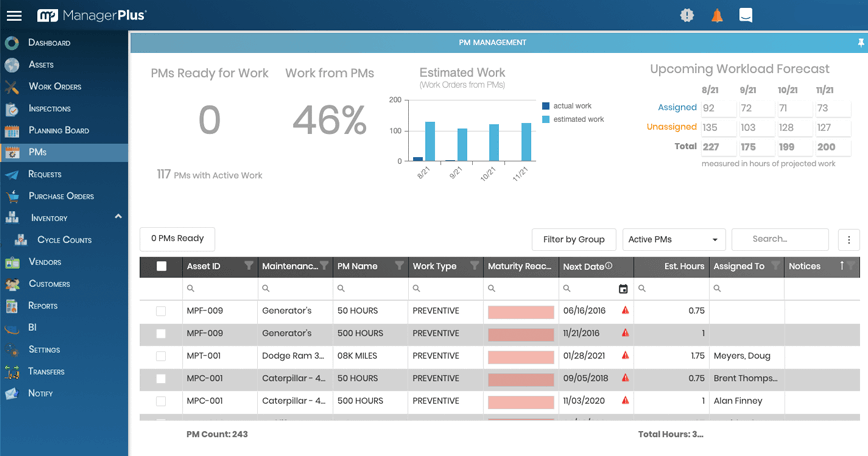

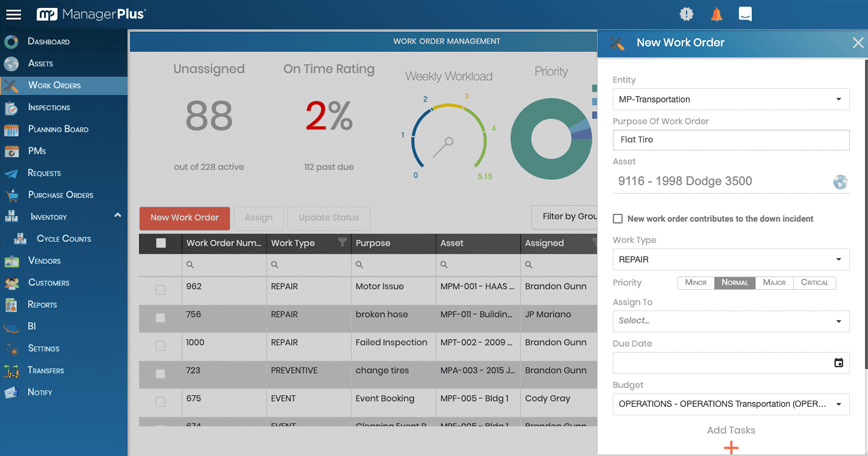

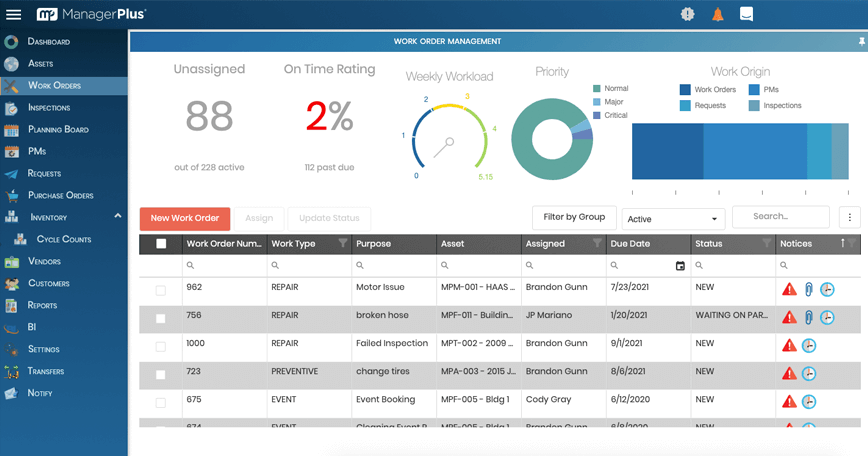

The key to a strong preventive maintenance program is staying on top of work orders. With ManagerPlus, you can set work orders to automatically generate once an asset has reached predetermined metrics such as usage hours or mileage.

Up to 50% of all unplanned equipment downtime can be traced back to a lack of parts. Know exactly how many parts you have, where they’re going, and when it’s time to order more all within ManagerPlus Lightning. We’ll even take the hassle out of auditing your inventory for you as part of our customized implementation packages.

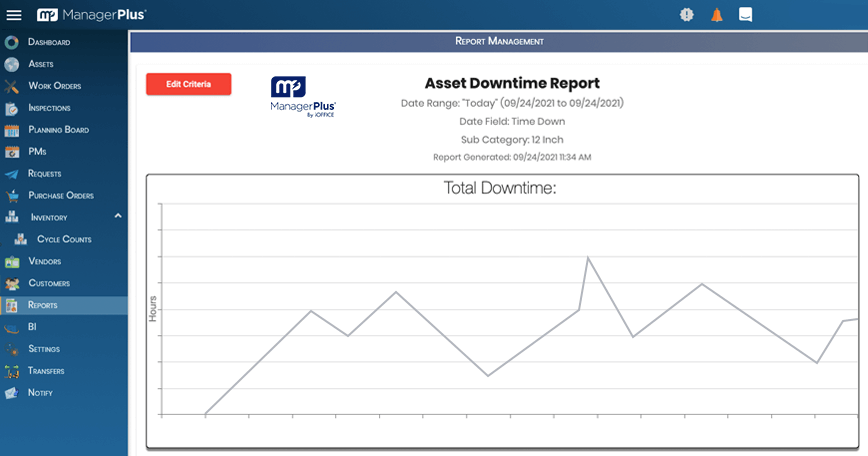

You need to know how your assets are performing so you can make informed decision about investing in them. Use ManagerPlus to see Business Intelligence (BI) reports based on the KPIs that matter most to your company and make the right decisions about how to invest in your assets.

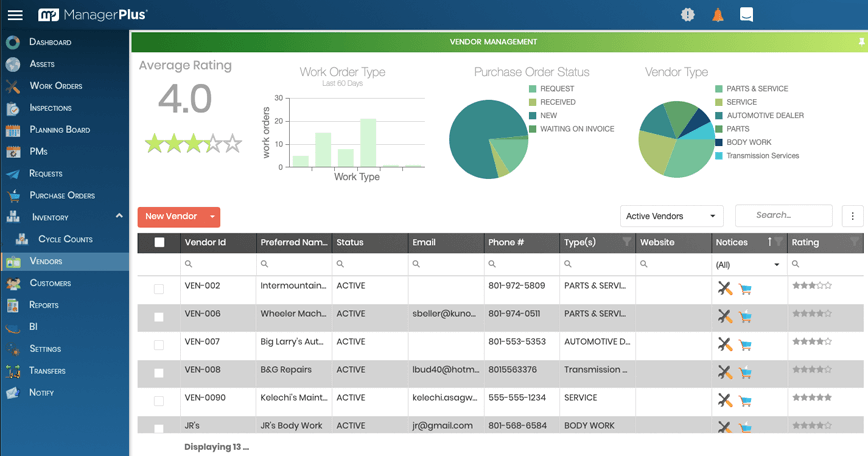

Endlessly calling and emailing with vendors to schedule maintenance work wastes time and money. From the Vendor Portal within ManagerPlus, you can easily assign vendors to unique or recurring maintenance work where they can perform the work, add photos, and attach an invoice.

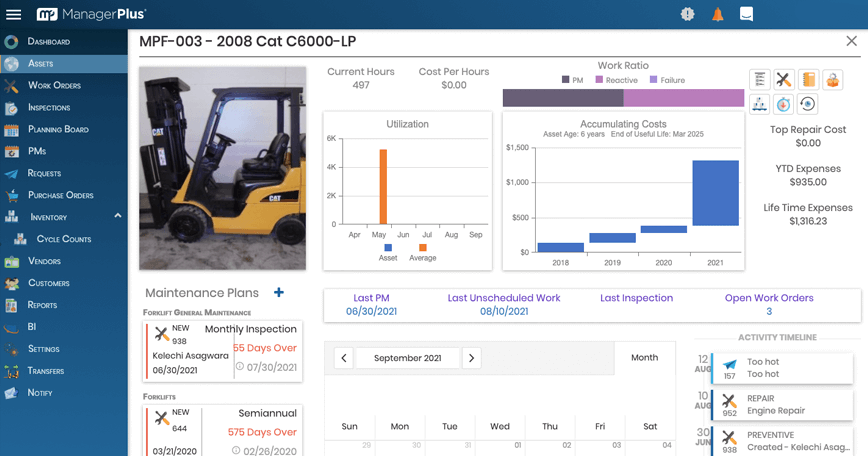

If you don’t know how much time and money you’re putting into your assets, you can’t make an informed decision about when to replace them. You can see the entire work history for your assets in ManagerPlus so you can compare their work and performance over time and know the best way to invest in them.

Failing compliance audits can be expensive with fines and potentially even legislation. Not to mention the possibility of putting your crew in danger. Avoid unnecessary costs and keep your team safe by having always up-to-date inspection reports that are always available when it’s time for an audit.

Everyone can communicate seamlessly to close the loop on all your asset-related tasks without the price of full access.

With an “ecosystem” of access to your ManagerPlus Lightning platform, no one has to rekey data or input information as a separate task.

Only pay for the features your teams need, based on their individual roles. That way, you gain more EAM capabilities for less money.

Select the features and enter the number of users you need to get an instant estimate.

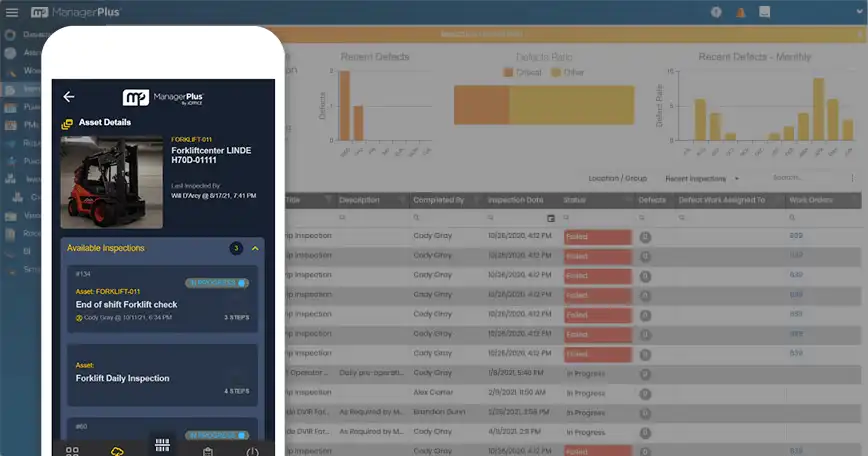

You need a solution that can keep up with your mobile workforce and the Work Companion app lets your technicians perform their tasks from wherever they are. They simply scan a QR code on the asset and the correct work order and any relevant information pulls up instantly so they can get to work fast.

ManagerPlus is your “eye-in-the-sky” to give you detailed insight into how well, or how poorly, your assets are performing. Track maintenance history, inventory, internal and external work orders, and even generate cost reports based on the KPIs most important to your company. Manage every part of your asset lifecycle with our cradle-to-grave digital management solution.

A robust CMMS solution is a key component of any good preventive maintenance program. Use ManagerPlus to stay one step ahead of critical maintenance work by knowing when you need to repair your assets before they fail. Track asset maintenance history to see what assets are ready to be replaced.

Make your assets work for you by using our best-in-class EAM to stay on top of all your maintenance work. From replacing light bulbs to vital maintenance on your most critical assets. Take control of your asset maintenance and repair operations with ManagerPlus Lightning EAM.

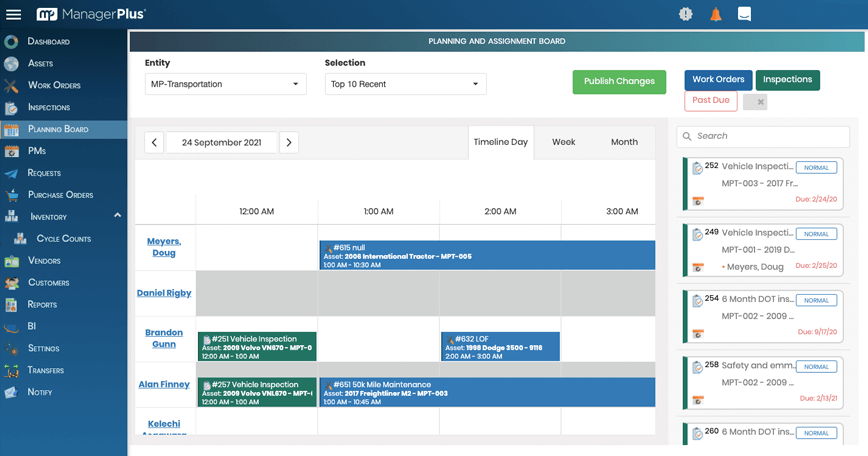

Plan critical maintenance work with automated PM schedules and drag-and-drop calendars.Keep your assets running longer and prevent unplanned downtime with a robust preventive maintenance program. With ManagerPlus, you can track your asset’s health and automatically assign work orders when critical maintenance work is needed before it’s too late.

By nature a preventive maintenance program is always evolving as you acquire more assets and you need a solution that can track maintenance work across your operations. With ManagerPlus, view historical inspection records to see how you can save money, improve completion times and percentages, preserve valuable maintenance know-how, and more all from one platform.

Manage your PMs from start to finish with ManagerPlus Lightning. Automatically assign routine work based on predetermined metrics you establish so your team spends less time reacting to repairs and more time keeping your assets running.

Make your assets work for you by planning your preventive maintenance before a catastrophic asset failure. Use ManagerPlus to plan your preventive maintenance on your schedule so assets only go offline when you want them to.

No more calling and emailing vendors to coordinate maintenance work. Send work orders to your vendors where they can complete the job, add photos, and attach an invoice all from the same software that manages your internal work orders.

Vendors receive a link to the correct work order so there’s no need to deal with logins or extra licenses.

Fix your equipment before it fails with ManagerPlus Lightning. The moment your assets start being tracked by our software, work orders can automatically be generated and assigned to the right technicians to get the job done. And you can track historical work on your assets over time to make informed decisions on when it’s time to replace equipment.

You need to know where the gaps are in your asset management program before you can fill them. Generate business intelligence reports based on the KPIs that are most important to your business, so you know exactly how to optimize your assets.

Implementing EAM software at your company doesn’t have to be difficult. We’ve been building and implementing ManagerPlus for over 20 years, so our teams know how to get it right the first time. Begin optimizing your preventive maintenance program quickly with our customized implementation program built to meet your needs.

Training

Training Your success is important to us and our training experts are passionate about helping your team get the most out of our software. Every month our live webinars take an in-depth look at one of our features and all our past webinars are readily available to go back and watch at any time. Our online learning center also has hundreds of resources that cover every part of our software so you can easily find the answers you need.

Integrations/APIs

Integrations/APIs ManagerPlus offers support for a wide range of third-party data tracking systems. We can seamlessly integrate with the tracking system you are already using so you don’t lose any critical data. Our platform is also built on an open API so if you use a proprietary system, your developers can easily build it right into ManagerPlus.