Strong maintenance programs are vital to the success of any company, but how can you know if your team is performing where they need to be to get the most out of your assets?

Preventive maintenance compliance is one of the key maintenance metrics companies use to determine how well their maintenance teams are keeping up with PM tasks and repairs. Simply having a good preventive maintenance program in place isn’t very effective if your team isn’t executing it well.

Let’s look at how to calculate your preventive maintenance compliance and what you can do to keep your score high.

What is preventive maintenance compliance?

The best way to maintain assets is with a robust preventive maintenance program. The goal is to continually monitor the asset to find and eliminate any potential issues that would cause the asset to fail. For every PM that is missed, the risk of failure increases.

PM compliance is a metric you can use to help you determine how effective your preventive maintenance program is. It tells you how successful your team has been in completing PM tasks on time so you can better optimize your workflows and find areas for improvement.

The 10% rule

The goal of preventive maintenance is to spot issues and fix them before they become problems, so any late or missed PMs increase the chance of something going wrong. That’s why we measure compliance so we can work to reduce and eliminate late or skipped PMs.

The problem with the compliance calculation, however, is that it doesn’t account for late PMs. The formula only considers completed PMs and doesn’t care if they were completed on time, only if they were completed within the time frame specified.

For instance, if you’re evaluating your compliance over the past 90 days, but you had a PM that was supposed to be completed every 60 days that was late by 15 days, the formula still counts that as a completed PM and adds it to your score.

We all know that late PMs have the potential to be devastating to your organization, so we want to make sure we have a way of spotting and accounting for them. We do this with the 10% rule.

With the 10%, you only count PMs as meeting compliance if they are completed within a 10% time frame of their scheduled interval. In our 60-day example above, that would mean you would only count that PM as being completed if it was done within 6 days of the due date, not 15. That way you can still account for complete PMs while having a way to cut down on late work.

How to calculate PM compliance

Since PM compliance is all about helping you improve your preventive maintenance program, there are a few things you need to establish before you calculate it or the results won’t make much sense to you.

To calculate your compliance you need to:

- Develop and define a list of preventive maintenance tasks to be performed on your assets

- Establish a time frame for when you’re going to measure completion

- Execute the plan during the time period

- Monitor and track the number of tasks completed on time (remember the 10% rule)

Once you’ve done that, you can calculate your compliance score.

It’s important to keep in mind that the preventive maintenance compliance score includes only preventive maintenance tasks. Only include regularly schedule preventive maintenance tasks in your formula. Reactive maintenance tasks should not be considered because they are not regularly scheduled and are by definition unpredictable.

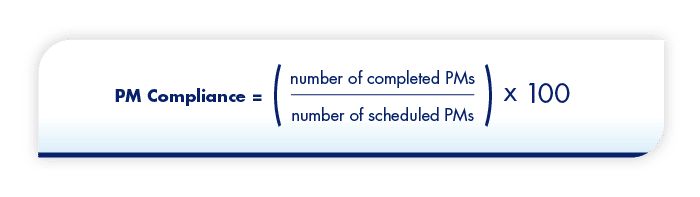

Preventive maintenance compliance formula

Your organization’s PM compliance is the percentage of total completed PMs in a set period of time. To find it, divide the total number of completed PMs by the total number of scheduled PMs within that period, then multiply the result by 100.

The time period you set for your scheduled PMs is up to you. Most organizations build their maintenance calendar out by week, so you could evaluate your compliance weekly, but evaluating over 90 days might give you a better overall picture of your compliance.

The time period you set for your scheduled PMs is up to you. Most organizations build their maintenance calendar out by week, so you could evaluate your compliance weekly, but evaluating over 90 days might give you a better overall picture of your compliance.

Preventive maintenance compliance example

Let’s say your organization had 300 PMs scheduled for the previous quarter and, taking the 10% rule into account, you completed 230 of them.

That would mean your compliance was:

PM compliance = 230 completed /300 scheduled x 100

PM compliance = .766 x 100

PM compliance = 77%

The industry-accepted gold standard for compliance is 90% or higher, but most companies typically fall between 40% and 90%.

How to stay compliant

A low compliance score can shed light on some of the bigger issues your maintenance team might be struggling with in your preventive maintenance program. If your score is lower than you’d like it to be, there are some practical steps you can take to improve your PM operations.

- Evaluate your PM task list

- Streamline your workflows

- Intelligently tackle your backlog

Eliminate unnecessary tasks

The most dangerous words for any maintenance team are: “That’s how we’ve always done it.” Adopting this mindset to maintenance work is not only inefficient but it can also lead to unnecessary expenses, a greater chance of equipment failure, or worse, someone getting hurt.

You’ll want to make sure that you regularly evaluate your list of PM tasks to see if there are items that might be outdated or even unnecessary. You don’t need to assign a tech to lubricate a machine that you don’t have anymore. If these tasks are still being assigned but are not getting completed because techs aren’t paying attention to them anymore, your score will not accurately reflect your team’s efficiency.

This is also why it’s important to stay up to date on industry standards and best practices. They are frequently changed and updated as new technology becomes available or new methods are discovered. Simply continuing to perform a task the same way you’ve always done it may not be the best way to do it anymore.

Simplify PM tasks and workflows

Often PM tasks don’t get done due to a lack of time or resources. Maintenance emergencies can quickly arise and less time-sensitive tasks can get put on hold, only to be forgotten about later. Implementing an easy way to assign and follow up with your preventive maintenance tasks is vital to improving your compliance score.

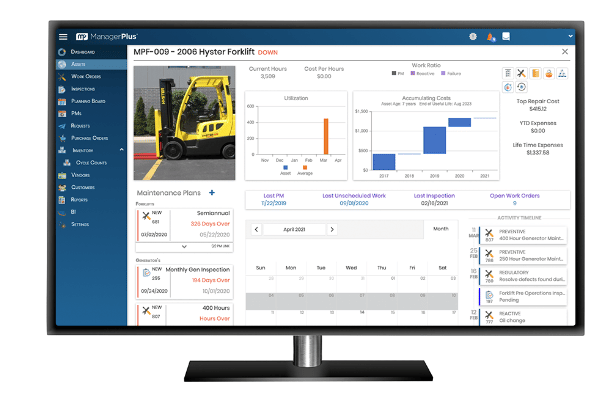

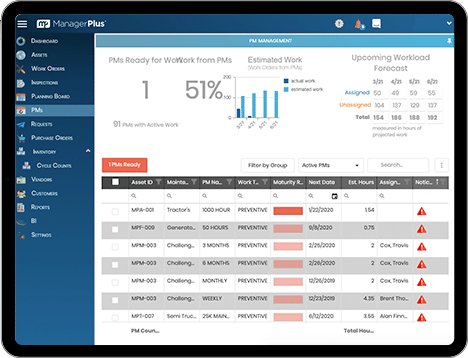

The best way to do that is with preventive maintenance software. With the right system, you can set PM schedules for your equipment and automatically generate and assign work orders when it’s time for repairs. For more complex tasks, you can create custom templates with notes, user manuals, and advice from senior techs to make sure the job gets done right the first time.

With cloud-based software, all of your information is updated in real time and always available whenever you need it. The moment the technician closes out, you’ll be notified so you can follow up if there are any questions.

The best part of full-service preventive maintenance software like ManagerPlus is that it’s mobile-friendly, so it’s simple to use and you can access it from anyway. We all know that maintenance work doesn’t happen behind a desk, so you need a solution that you can easily take with you. ManagerPlus works seamlessly across laptops, tablets, and smartphones, so you’ve always got everything you need in the palm of your hand.

You’ll also want your software solution to have mobile apps for smartphones and tablets so your team can perform inspections and access and close out work orders from wherever they are. The best preventive maintenance software systems will allow you to generate barcodes for each asset so your operators can scan them and perform visual inspections quickly, then immediately notify a tech if the equipment fails inspection.

Analyze your backlog to tackle it intelligently

Having a backlog is a part of any maintenance program, but it’s not necessarily a bad thing. The key is to determine which outstanding PMs will have the most impact on your operations. One way to determine this by looking at your asset criticality to see which assets are the most influential to production and thus would be the most devastating if they went offline unexpectedly.

Once you have this, you can better assign resources to tackle your backlog intelligently.

Use preventive maintenance software to track and improve compliance

Understanding compliance and how to improve it is important, but as with any job, you need the right tools to complete the task. Preventive maintenance software is the best way to develop, implement, and track your preventive maintenance program so you can easily check your compliance anytime you need to.

With ManagerPlus you can do things like:

- Automate PM schedules

- Streamline work order processes

- Track progress over time

Automate your PM schedules to maintain compliance

Developing and implement a preventive maintenance program can be tricky enough as it is, but keeping up with can be even harder, especially if you’re still using paper and Excel spreadsheets to manage everything. In that case, everyone has to hope that someone, usually the maintenance manager, remembers when it’s time for work to be done so critical equipment doesn’t fail.

With preventive maintenance software, you can input your PM schedules and your team will be automatically notified about the job and they can scan the asset to access the work order and any relevant information they need right on their tablet or smartphone. You can customize the work orders to include any required parts from inventory, manuals, or notes from senior technicians, and to require photos or signatures of complete tasks.

Having everything automated and updated instantly in the cloud makes improving your PM compliance a whole lot easier.

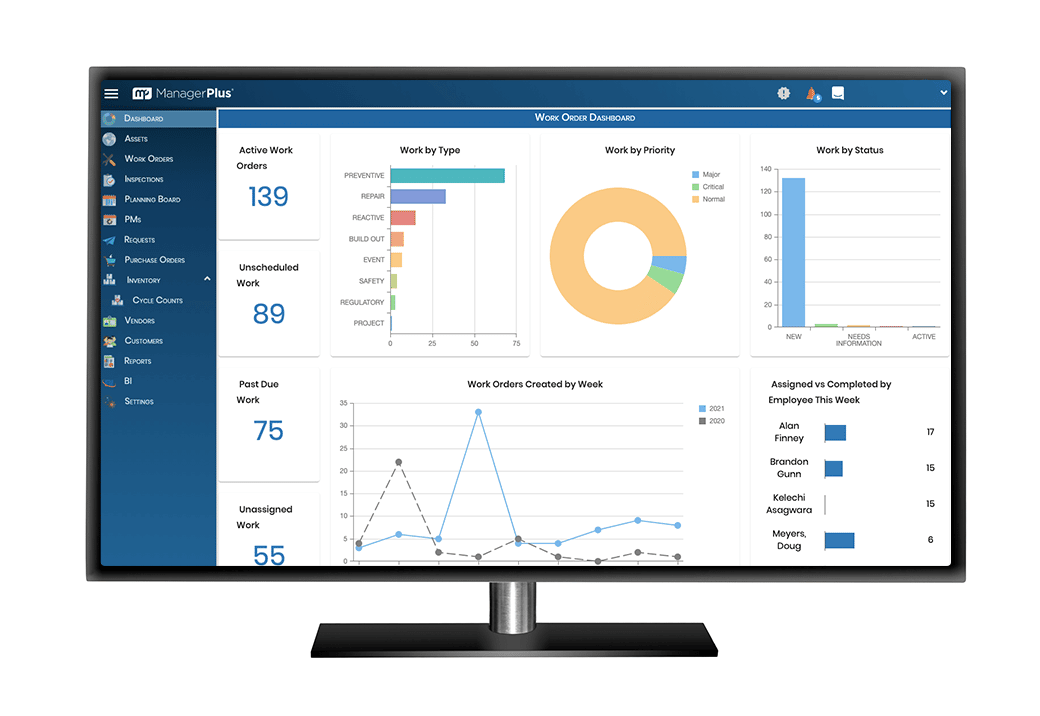

Cut the hassle from work order workflows

Work orders are the lifeblood of any maintenance team but many organizations still rely on paper and spreadsheets for their work order processes which are cumbersome and frustrating. Having to do 30 minutes of paperwork for a 10-minute repair job is extremely inefficient and annoying.

When you implement good preventive software, you can significantly cut down on the headaches and wasted time of inefficient work order workflows. The interface and dashboards are mobile-friendly so everyone on your team can learn to use them quickly, even the more tech-averse folks.

If you’re using a cloud-based system, everything is updated automatically and your team can access them from anywhere so you don’t have to chase people down all across the facility or wait for them to come find you in your office.

Improving your compliance score is much easier when everything works seamlessly together.

Make sure you’re improving over time

It’s hard to know if you’re improving if you don’t know where you’ve been. Preventive maintenance software keeps track of every work order and stores them for you forever so you can easily go back and evaluate your team’s progress over time.

Instead of having to dig through filing cabinets and disorganized folders on your computer, you can generate a customized report in the software that compares your work and progress over time. You can set which KPIs you want to track and then see how well you’ve met your goals.

If you missed your target, you can quickly locate any inefficiencies or areas for improvement so you can be sure to hit it next time.

Next steps

Getting started with preventive maintenance software to improve your compliance score is simple. Our ManagerPlus experts have years of experience in the industry and are ready to help answer your questions or even schedule a live demo of our software so you can see it for yourself.

Executive summary

Executive summary

Maintaining PM compliance is vital to improving your preventive maintenance program and keeping your equipment online. A strong PM program not only increases equipment uptime but it also helps extend the expected life cycle of your assets so you can use them longer before having to replace them.

The key to being able to track and improve your PM compliance is a strong preventive maintenance software like ManagerPlus. With it, you can automatically assign and track all your PM work orders and see how your team performs over time. The simple drag-and-drop maintenance calendar lets you quickly reallocate resources where you need to so you can improve your completion time and percentage.

You can also generate detailed reports on all your operations on the KPIs that are most important to your business so you can make informed decisions on when and how to invest in your assets and your team.