The term “compliance” tends to have an unpleasant connotation, but the truth is that it’s really a good thing all around.

Maintaining compliance keeps workers safe while on the job and it helps your organization ensure you’re producing a quality product and following industry best practices.

While there are challenges to maintaining compliance, with the right asset management software, it doesn’t have to be a painful process.

What is asset management compliance?

Compliance can refer to several different things, but in general, it relates to an organization’s adherence to a set of standards and guidelines accepted by the industry at large.

There are essentially two types of compliance:

- Internal compliance

- External compliance

Internal compliance is adhering to a set of standards and guidelines set within the company itself. This can be things like the process for requesting time off or how often you need to change your password. Any standards or guidelines that are determined by the senior leadership of your organization relate to internal compliance.

External compliance relates to the rules and regulations determined by authorities and regulatory agencies outside of your organization. Often these are government bodies that develop rules and requirements for each industry, but many times they can be standards and best practices developed by private companies as well.

Standard vs. regulation

Before we go much further, it’s important to understand the differences between standards and regulations. An easy way to think about it is that a regulation is usually required by law and tells you what you’re supposed to do while a standard is developed by professionals in the industry that tells you how to do it.

Standards are, in large part, voluntary. They are suggestions and recommendations for how to accomplish a certain task or goal in the most efficient way possible. They have been developed and improved upon over the years by widely recognized experts in the industry.

Thanks to a process called “incorporation by reference”, many of those standards have become regulations. It happens when a government regulation (guideline you’re required to adhere to by law) includes reference to an industry standard, thus making it enforceable.

Compliance with OSHA

In the U.S., the Occupational Safety and Health Administration (OSHA) develops and enforces most of the government regulations related to the workplace or job site. These are almost always related to keeping workers safe and you are required to adhere to them by law or your company will face consequences such as fines or possibly even litigation.

Compliance with ISO

ISO develops standards for industries all over the world and the goal is to give your organization a set of best practices that you can use to ensure keep everyone safe and deliver a quality product. These standards are voluntary but as we mentioned, they are often referenced in OSHA regulations meaning you can face penalties if you don’t adhere to them.

Remember, regulations (from OSHA) are what you have to do; standards (from ISO) give you a roadmap for how you can comply with those regulations.

Consequences of non-compliance

The consequences of failing to maintain compliance can vary and may include some things you might not think about.

Non-compliance can lead to things like:

- Fines

- Loss of reputation

- Litigation

- Suspension or revocation of business license

- Equipment downtime

Fines

The most common consequence for not complying with OSHA regulations is a fine. They can range anywhere from just a few hundred dollars to hundreds of thousands of dollars. In fact, in 2018, the metal manufacturing industry in the U.S. was fined more than $8.7 million.

The dollar amount of these fines can add up quite quickly so you’ll want to make sure you’re in compliance to avoid hefty fines.

Loss of customers due to a bad reputation

No one wants to buy from companies they don’t trust, and if your company develops a reputation of regularly failing compliance audits, you’ll quickly begin losing customers. Remember, OSHA regulations are almost always about keeping workers safe, and your customers will want to know you’re doing your part.

Damaging legislation

Many times, one of the most difficult things for a company to recover from is expensive, drawn-out lawsuits. There are countless stories of companies that have gone out of business because they could not afford the damages suffered from a painful lawsuit.

If a worker is injured at your factory and it comes to light that you weren’t in compliance with the applicable safety requirements, you could be in a lot of trouble.

Loss of ability to conduct business

In most developed countries, you’re required to obtain a license from the government in order to run your business. The other side of that coin is that if you continue to fail to maintain compliance, then you’re business license could be suspended or revoked.

Cost of equipment downtime

Most standards and regulations revolve around keeping workers safe and one of the best ways to do that is to make sure equipment runs as it’s supposed to. Many of the ISO standards provide guidelines and best practices for keeping assets running the way they were intended.

They detail things like how to set up a good preventive maintenance program to anticipate problems and repair your assets before they break.

Challenges of maintaining compliance

Maintaining compliance can be challenging but it is worth the effort. It may require your organization to develop and implement new policies and procedures but that is a lot better in the long run than facing fines, litigation, or worse.

Some of the most common challenges companies face with maintaining compliance are:

- Constantly changing standards and regulations

- Inaccurate internal data

- Inconsistent internal baselines

Always stay one step ahead

Regulations and best practices for most industries are constantly evolving and changing. Compliance is not something you achieve once, then don’t have to worry about ever again.

In fact, one of the easiest ways to fall out of compliance is by not updating your policies, procedures, and equipment as often as you should. Many government regulations have time restrictions on them so if you were supposed to replace a piece of equipment after 10 years and you’re in year 12, you’re now out of compliance.

Another common way to fall out of compliance is to not be away of a change in the rules. As technology advances and industry practices change, many times the rules change with them.

For example, not long ago the Canadian government updated many of its rules for food processors. The reasoning was simply that the technology had evolved, and the rules had been established when most of the country’s food was grown locally. That was no longer the case so new rules needed to be put in place.

Keep your data updated

With everything you have to keep track of, it can be difficult to make sure all your inspections and compliance information is accurate and up to date. The last thing you want is for the auditor to come by and you can’t find or don’t have you’re updated inspection reports.

The easiest way to ensure all your data is always accurate and updated is to use enterprise asset management software (EAM) to help you keep track of everything. With the right EAM software, all of your data lives in the cloud so the moment something is updated or an inspection is performed, you’ll know.

Keep everyone on the same page

Does your team ever suffer from miscommunication? One of the hardest parts of maintaining compliance can be if every team in your organization is working from different starting points. It’s hard to keep everyone going in the same direction if no one knows where to start.

You’ll want to develop consistent baseline compliance protocols and documentation standards at your company so everyone is working together on the same page.

How to maintain compliance

The best way to overcome the challenges of maintaining compliance is to develop a plan for your organization and stick to it. These guidelines are a good place to start.

Appoint a compliance manager

If you don’t already have a compliance department or manager at your company, you should find one. Sometimes HR departments will know about compliance regulations, but you’ll want to have someone on your specific team who can take charge of ensuring you’re in compliance. It’s a good idea for this person to be in a management position because chances are they might need to have some tough conversations.

It’s easy to make the compliance manager the bad guy on the team but the truth is, if you fall out of compliance it’s bad for everyone. Keeping people safe should never be looked down upon.

Understand your legal requirements

It’s virtually impossible for anyone to have full knowledge of every single regulation and standard you’re required to adhere to, but the leadership of your department should at least have a basic idea. At the very least, they should know how to quickly find out that information if there’s ever a question.

Perform regular internal audits

Audits are a part of life if you work with heavy equipment and the last thing you want is to be unprepared. A good way to make sure you’re keeping things on track is to schedule your own audits in addition to the ones required by law. Hiring a third-party company to perform an audit of your systems is a great way to get a risk-free assessment of how well you’re maintaining compliance.

If you don’t quite have the resources to regularly contract out inspections, then you could still have someone on your team, ideally the compliance person, regularly monitor your compliance. Simply having them walk through the warehouse floor and look for how well you’re adhering to your compliance plan is a great way to keep things on track.

Automate data entry

Undoubtedly the best way to maintain compliance is to automate your data entry processes. If you’re still using paper and spreadsheets to run your asset management and maintenance operations, it’s nearly impossible to have updated, accurate information.

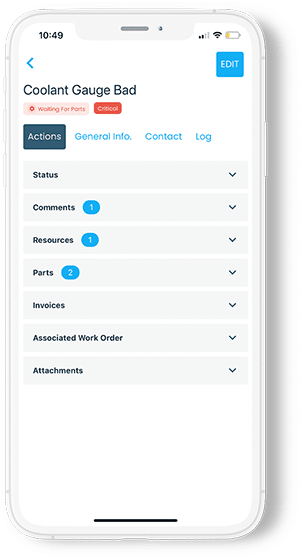

For example, if you’re using good EAM software, your operators and techs can simply scan a barcode on your assets to pull up the relevant asset information, perform inspection or maintenance tasks, and close out work orders from wherever they are. And all the information is updated instantly so you don’t have to waste time trying to track down someone to ask about an inspection report.

EAM software can help

As with any maintenance task, the job is a whole lot easier with the right tool in hand. Many of the challenges of maintaining compliance can be easily overcome with the right asset management software.

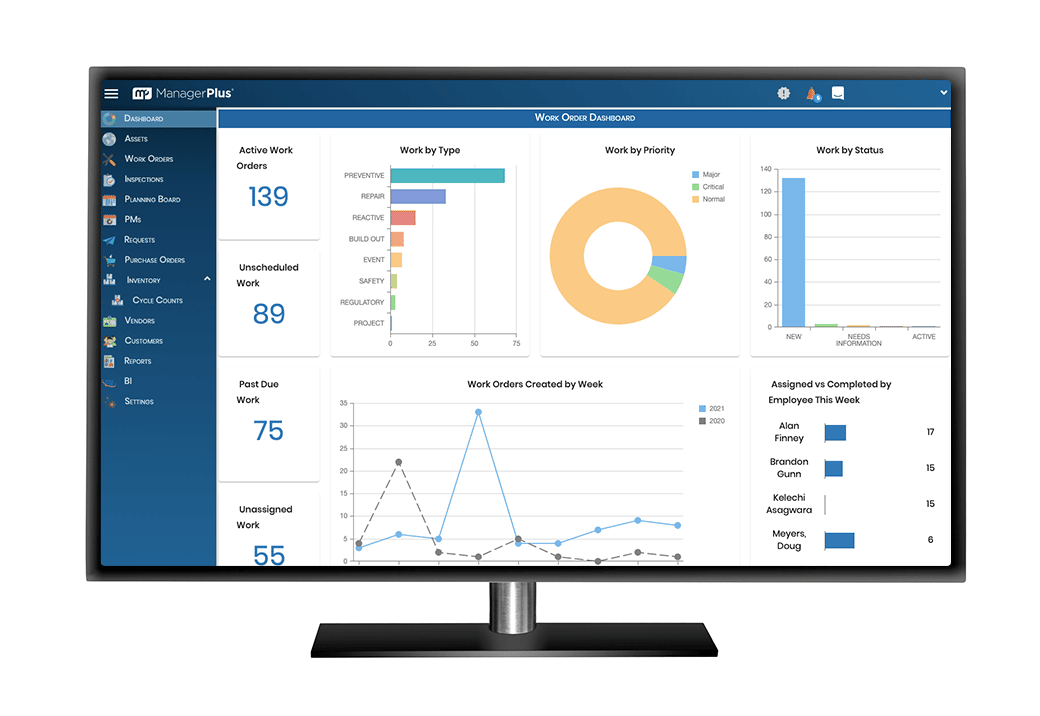

Our ManagerPlus EAM solution can help you do things like:

- Track and store updated inspection reports

- Develop and operate a preventive maintenance program

- Track important data seamlessly across your teams

- Generate business intelligence reports on important KPIs

The best way to see how ManagerPlus helps you maintain compliance is by watching it in action. Simply reach out to our teams and you can schedule a live demo where you can ask questions and see first-hand how you can streamline your asset operations and keep your organization in compliance with ManagerPlus.

In summary: You can’t afford to wait to invest in EAM software

Failing to maintain compliance can have devastating consequences for your organization. Everything from fines to damaging litigation can all be the result of not adhering to government regulation and industry-accepted standards. EAM software can help you overcome all the challenges of maintaining compliance and ensure you never have to face an audit unprepared.