Inventory is a necessary cost for every organization, but can it also help improve your ROI?

Not all inventory is the same, and how you manage it has a big impact on your operations.

Inventory control systems help ensure you get the right parts to the right place at the right time, all while improving productivity.

What is inventory control?

Controlling inventory is all about taking command of the items and parts scattered across your facilities to make sure you’re getting the most for your money. Every stage of their journey from purchasing to disposal is optimized to ensure that nothing is wasted, and every item is used efficiently.

There are many goals for improving inventory control but some of the main ones are to reduce cost, improve productivity, and boost ROI across your operations.

How does inventory control improve productivity?

Many organizations don’t give inventory much thought other than that it’s a necessary cost of doing business that you want to keep as low as possible. Often this is done by purchasing parts in bulk to score a “great deal” or simply waiting until you’re out of stock to order more.

The problem is that you’re leaving money on the table when it comes to your inventory. With the advent of Industry 4.0 and the vast amounts of data and automation available, it’s easy to streamline inventory operations to optimize efficiency and lower costs.

What are the different types of inventory?

Before we can get into the different types of control systems, we need to establish what types of inventory items your organization has. There are four types of inventory items:

- Raw materials

- Work-in-progress (WIP)

- Finished goods

- MRO

Every item that comes through your company will be classified into one of these four categories.

Raw materials

This encompasses everything your company needs to produce the goods you sell to your customers, and raw materials can vary among organizations. For example, if you manufacture cars, then your raw materials are engine parts, doors, tires, and everything else needed to assemble the car that gets shipped to the dealership. For the supplier who sells you the parts you use to assembler your cars, they need things like metal, rubber, chemicals, and other materials to produce the items you use.

Work-in-progress (WIP)

These are items that are currently being produced at your facility but are not yet completed and ready for sale. These can include things that are currently being processed or items that are finished but have not yet been inspected and given final approval for sale. Going back to the car example, a WIP item would be the car engine. It has been assembled but not yet put into the vehicle so is not ready to be sold.

Finished goods

As the name suggests, finished goods are items that have made it all the way through your operations and are ready to be sold and shipped.

MRO

Maintenance, repair, and operations (MRO) inventory are items that you need to have on hand for your maintenance and operations team to keep your operations running. MRO inventory is a broad category that includes everything from lubrication for your machines to pen and paper for the front office to light bulbs, including janitorial supplies. Any items that are needed to perform your day-to-day operations.

The tricky part is that sometimes items in other categories can also be classified as MRO inventory. Consider nuts and bolts: you need them to assemble your vehicles, but your technicians also need them to repair your machines. Essentially, any item that does not directly go into a finished product is part of MRO.

What are the different types of inventory control systems?

Now that we know what types of inventory you have, let’s establish the different ways to control them. There are two types of inventory control systems:

- Periodic

- Perpetual

These two systems determine how your company categorizes, accounts for, and moves inventory throughout your operations. They each have their uses, but most often the one you choose to implement at your business depends on the size of your inventory, the resources you have available, and how you choose to account for inventory.

Periodic

Periodic inventory control tracks your inventory with physical counts performed at specific times throughout the year. The numbers at the beginning of the cycle count are assumed to be the ending numbers of the most recent cycle count. One advantage of this system is that you can calculate the cost of your ending inventory using FIFO, LIFO, or any other accounting method you choose. Periodic systems are also relatively easy to implement and operate.

The downside of periodic systems is that they are performed using manual labor, so many times the business cannot be operating while performing a cycle count. Plus, as with any task where humans are involved, the risk of human error is potentially high, particularly if employees feel rushed to complete the process as quickly as possible to keep labor costs down.

It’s also difficult to locate the source of any mismatched numbers in a periodic system because so much time passes between counts that it’s hard to know when and where the numbers became off.

Smaller organizations tend to benefit more from periodic systems because the cost involved are more manageable with less inventory and fewer labor hours to consider.

![]()

Perpetual

Perpetual inventory control systems take a different approach. Instead of only tracking inventory at periodic intervals, you track each item throughout its journey across your facility. From the moment you receive it, to the moment it is used in your operations, sold, or scrapped, it’s tracked. You get up-to-the-minute data on precisely where your items are and what they’re being used for.

This data is gathered from sensors, barcodes, and scanners that keep tabs on items in real time, helping to eliminate errors from miscounts and helping your team pull inventory items more efficiently. The moment out-of-stock items are received and allocated to the proper bin, your team can be notified and begin using them immediately, instead of sitting on the shelf waiting for the next cycle count.

The challenges of perpetual systems are different that those for periodic systems. Instead of needing large amounts of labor to perform counts, you need to invest money upfront in the sensors, barcodes, scanners, software, and other technology that helps you collect your data. And the more locations you have, the more equipment you need to buy.

You’ll still need to perform cycle counts periodically to reconcile any incorrect numbers, but it’s far less often than with a periodic system.

Ultimately, periodic inventory control systems are typically best suited for smaller organizations with few inventory items to manage and track. For larger companies with hundreds of items to keep track of, a perpetual control system is the more cost-effective option.

How do I cost-effectively manage inventory?

Alright so, you need to control you inventory to keep your costs down, but what’s the best way to do that?

There are essentially three ways to manage inventory, regardless of what control system you use:

- Paper checklists

- Spreadsheets

- Inventory management software

Each system can be useful, but only one will help you keep costs down and improve your ROI. Let’s find out which one.

Pen and paper checklists

Believe it or not, there are still many companies that attempt to manage their entire inventory with a pen and paper. This can work, if you are a very small business with just a few items that aren’t very critical to your operations. Doing everything by hand significantly increases the potential for human error and it requires a lot of time spent away from more productive tasks.

Spreadsheets

The next step up from a pad of paper is spreadsheets. You can store an enormous amount of data in them, and your team can update them instantly as needed. The problem with spreadsheets is that when someone updates them, suddenly that specific version of the file is now the most up to date so if unless the next updates the exact same file, you no longer have a unified source of data.

Spreadsheets still require manual updates and modifications so you’re still spending money for someone to keep that spreadsheet updated. While they can get the job done in some cases, spreadsheets are still not the most cost-effective way to manage complex inventories.

Inventory management software

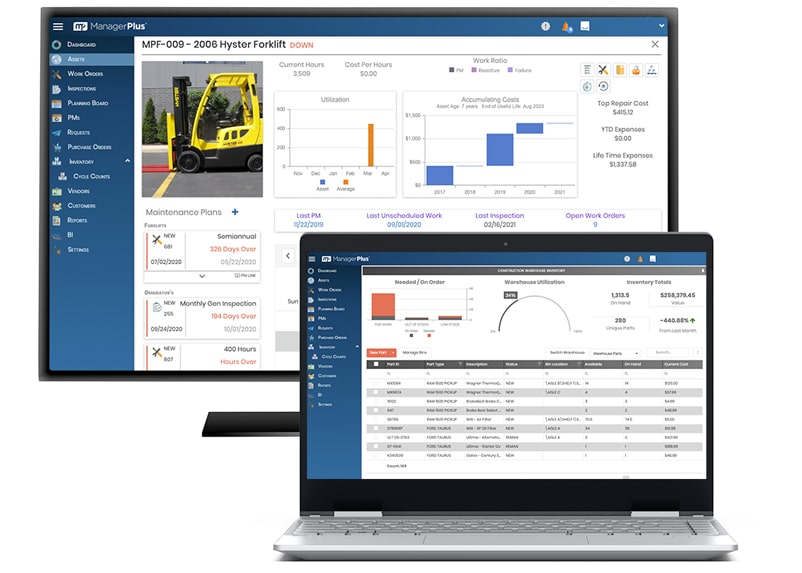

Data and automation are the tools of industry and are proven to help control costs and improve ROI. Apply these powerful tools to your inventory with inventory management software to get more from your inventory.

With this software, you can implement a robust perpetual control system and track every item across your entire operation, even across multiple facilities. The best part about this is that you can instantly see where you inventory costs are going. Instead of waiting to reconcile your inventory accounting a few times a year, you can quickly tell which parts are not being used efficiently and which parts you aren’t using as much. In fact, most organizations don’t use as much as 90% of their MRO inventory every year and your software solution can show you what parts aren’t being utilized efficiently.

Remember that money we were leaving on the table with inefficient purchasing and ordering methods for restocking inventory? Inventory management software helps ensure you don’t miss a single dollar. Set your min-max levels and you’ll be notified automatically when it’s time to order more so you’re not holding onto parts you don’t need, and you know you’re actually using every part that you buy.

An ongoing goal of any business is to keep costs low while improving efficiency and productivity. Decision makers are always looking to maximize returns on investment and make a better product faster and cheaper. That’s hard to do if you don’t really know where your costs are going.

When you’re tracking every inventory item across your operations, you get detailed reports on how efficiently you’re using your inventory and how you’re spending your money.

Effectively managed inventory also directly impacts your asset’s uptime. The more uptime you have, the more you’re producing, which means more widgets to sell. A recent report from the Aberdeen research group showed that as much as 50% of unplanned equipment downtime could be traced back to a lack of parts.

Keep costs low by not paying for inventory you don’t need, improve asset uptime so you’re making more product, and give your team the tools they need to work more efficiently with inventory management software.

Summary

Inventory control systems are the processes you put in place to keep track of the items in your company’s inventory. A periodic system updates inventory counts and set times throughout the year by using physical counts of each item in stock. Perpetual systems track items from receiving all the way until they’re used, sold, or scrapped. Although you can use paper checklists and spreadsheets to track inventory if you’re a small business with few items, inventory management software is the most cost-effective way to manage inventory.

Next steps

Ready to boost productivity and see more ROI from your inventory? Talk to our experts today about implementing ManagerPlus at your organization. Schedule a one-on-one call so you can share the challenges you’re facing to keep costs low, and they’ll walk you through our software and show you how to get more for your money.