Asset managers rely on equipment and vehicle inspections to assure safety first and foremost. Many see the whole process as a cumbersome chore, a drag on operations. But it doesn’t have to be that way.

That’s why we’ve created the ManagerPlus Inspection Module—a new feature in the Lightning enterprise asset management (EAM) platform that seriously streamlines the entire inspection process. With the Inspection Module, you can not only save time, you can also upgrade your protocols to “close the loop.”

In other words, you can tie together inspections and corrective actions seamlessly with clear communication between teams. That way nothing falls through the cracks. No critical repairs are missed. And your equipment and fleet vehicles are back online ASAP after any inspection failure.

Less time spent on inspections or repairs means more time in production and more time on the road. More productivity equals a better bottom line.

Replace paper checklists with digital inspections

Of course, inspections are more than just checklists. Today’s asset managers are shifting away from pencil-and-paper equipment inspections and Driver Vehicle Inspection Reports (DVIRs) in favor of digitally enabled inspection tools that collect data from anywhere and report it in real time.

Why? Because paper checklists are costly, wasteful, and harmful to the environment. Not to mention, paper is less secure and difficult to access on-demand. Instead, digital DVIRs and inspection processes are becoming the preferred solution.

They allow a faster end-to-end timeline as well as better reporting for regulatory compliance, such as the DVIRs required by the Federal Motor Carrier Safety Administration (FMCSA) for vehicle pre-trip inspections. With a digital solution, you also have an audit trail that proves your company follows safety guidelines, strong protection in the event of an accident.

What is the ManagerPlus Lightning Inspection Module?

The new Inspection Module consists of three elements, one for each role:

- Asset Manager — EAM inspection protocols, dashboards, reporting capabilities, and other business intelligence tools

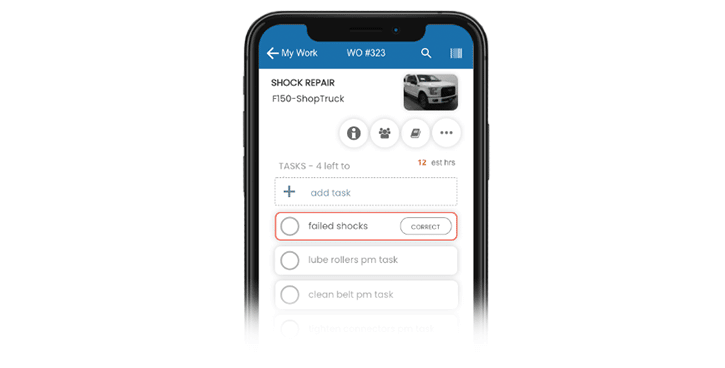

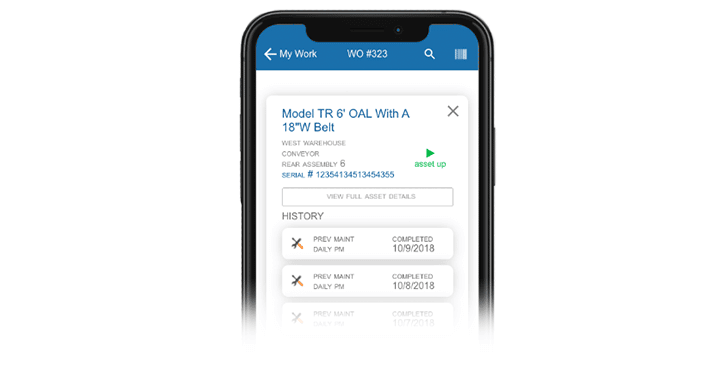

- Operator — The Operator Companion mobile tool allows operators to collect inspection data from anywhere and prompt corrective actions in real time

- Technician — The Work Companion feature outlines standard operating procedures related to corrective actions to assure quality

Each aspect of the Inspection Module is tailored to the person using it. With its intuitive interface, the module helps everyone close the loop on inspections in a methodical way.

Using the Inspection Module, asset managers can:

- Design custom checklists for inspections, based on DVIR rules, equipment manufacturers’ recommendations, or institutional insights

- Configure pass/fail protocols and failure codes

- View inspection data in real time

- View corrective actions in real time

- Set standard operating procedures for corrective actions

- Assure accountability with mandatory digital sign offs

- Analyze and report data across the enterprise

- Produce inspection reports for compliance audits anytime

Additionally, the Operator Companion allows equipment and fleet operators to:

- Conduct inspections on mobile devices from the road, the shop floor, or anywhere

- File reports in real time

- Record data quickly with simple pass/fail buttons

- Capture photos of passing or failing items and add them to the asset record

- Prompt immediate work orders to quickly advance the corrective-action step of the process

And the Work Companion allows your technician teams to:

- Receive inspection-related work orders quickly

- Complete corrective actions following standard operating procedures

- Verify repair quality by referencing photos and instructions

- Cue operators when assets are ready for re-inspection and deployment

By using a complete, methodical process on the ManagerPlus Lightning EAM platform, you can transform inspections from a clunky, disjointed chore into a streamlined protocol that closes the loop on activities as well as communication. Inspections become the easiest part of your day.

How does the Inspection Module close the loop?

Face it, inspections take time. And every minute an asset is idle in the inspections holding pattern is a minute it’s not online producing your products or delivering your cargo.

You need maximum uptime for your machines. You need DVIR pre-trip inspections completed in a timely manner. The only way to do that is to streamline the inspections process and make it as efficient as possible.

With the ManagerPlus Inspection Module, you create a seamless system that keeps the activity advancing automatically—without the delays of handoffs, phone calls, emails, or other manual cues. Each step in the process follows with minimal effort.

Did that truck fail an inspection because of low tire pressure? No worries. Your operator can simply tap the “fail” button and generate a work order for the mechanic in seconds.

Does your machine have a faulty pressure valve? Get it fixed quickly and according to standard operating procedures without the delays of new, separate schedules and requests.

Has a regulator requested evidence of your safety compliance? Easy. Just run the inspections report in ManagerPlus Lightning and deliver it right away.

Time is money. And the ManagerPlus Lightning Inspection Module was designed to save both.

Why are asset inspections important?

Everyone knows inspections on vehicles and equipment are an essential part of the workday. But they translate into dollars and cents, too.

Safety

Safety is the key reason why you need an inspections process. When you verify safety every day, you protect your operators and the community.

The ManagerPlus Lightning Inspection Module helps you avoid the costly pitfalls of “pencil whipping”—the mindless and unsafe habit of operators who hurriedly check off an inspection item without really looking at the asset. That leads to safety issues.

For example, when an operator absentmindedly checks off a windshield inspection without actually looking at the windshield, the small chip they missed can quickly turn into a big crack that impairs the driver’s vision on the road.

With a digital process that includes photo verification and itemized pass/fail sign offs, you assure inspections are in fact completed. Such assurance can help you avoid more costly downstream repairs as well legal trouble in the event of an accident.

Regulations such as DVIR

Under 49 CFR 396.11 and 396.13, most fleet operators are obligated to complete DVIRs.

Your EAM provides the ideal platform to store DVIRs and connect them to corrective actions. By keeping good inspection records, you can avoid regulatory fines, which can be as high as $12,695 simply for a lack of recordkeeping. Other violations carry additional penalties.

It only makes sense to use a digital process to capture and store your DVIRs. Plus, the time you save having regulatory audit trails at your fingertips is time you can spend on more important business issues.

Business decisions

Beyond savings on maintenance costs and regulatory fines, a digital inspection process delivers better business intelligence.

Have you noticed a certain fleet vehicle often fails inspections? Maybe it’s time to replace it. The cost of ongoing maintenance might not be worth it any longer.

Use your Inspections Module data to keep tabs on urgent repair costs, asset life cycles, and resource allocation. That rich field of data adds up to smart decisions that boost profits.

Don’t waste another minute on unreliable paper inspection reports. Schedule a demo to see how the ManagerPlus Inspection Module can streamline your inspections and improve your business.