From manufacturing to food and beverage, a huge range of industries rely on warehouses. Warehouses are central hubs where industries store, organize, and manage all kinds of goods, which makes them a major component of just about any goods based business.

So it’s no surprise to learn that managing those warehouses efficiently is an essential process. That’s where warehouse management systems come in.

What is a warehouse management system (WMS)?

Warehouse management is any process that involves organizing or directing the operations of a warehouse. That means anything going in or coming out, and all of the internal operations where goods are managed — all of that falls under warehouse management.

A WMS, by that same token, is a system that facilitates that management process. Usually that’s some kind of software which automates all or some of the management process.

How does a WMS work?

Imagine that warehouses are kind of like the heart in your body. If the warehouse is responsible for storing and pumping out goods to a body of stores and consumers, a WMS is like the electrical signals that tell the heart when to beat.

Of course, that’s only part of the picture. While a WMS can be generalized, it’s actually a whole ecosystem of apps, software, and specific process automation tools that come together to optimize and improve the functionality of warehouses.

So while the overall goal of WMS is to improve the efficiency and function of a warehouse, there are a bunch of smaller, individual components that affect specific processes. It could be an automated system for tracking incoming and outgoing bulk goods, or it could be a scheduling software that tells you how long certain goods have been in storage compared to their overall shelf life.

Who benefits from a WMS?

Any industry with a wealth of warehouses, goods storage needs, or high-volume goods management benefits from a WMS.

Some of the most common industries include:

- Wholesale Distributors

- Outside Logistics Providers

- Food, Beverage, and Produce

- Retail

- Manufacturing

- Healthcare

Wholesale Distributors

Wholesale distributors are essentially in the business of stocking up on bulk goods then reselling them or distributing them for resale. As you can imagine, a WMS is extremely useful for tracking the sheer quantity of goods, as well as organizing the distribution process across a number of resellers.

One of the main benefits here is organization automation. Say you want to track every piece and pallet in your warehouse, and then organize them by date or account. A good way to do that is to use a WMS to automate that process and automatically catalog inventory as it’s checked in according to pre-determined conditions.

So now you have a list of goods organized by intake date, related accounts, and location within the warehouse. Compare that to manually scanning or generating a similar list through outdated tech like a simple spreadsheet? You’re losing a lot of time and potential business.

Logistics Providers

Managing logistics for other businesses has grown into a business of its own which naturally includes shipping and storage management. Logistics providers offering warehouse management or product handling services certainly benefit from a warehouse management system.

In this case, the primary benefit is similar to the wholesale industry. Where the wholesalers are acquiring bulk goods and reselling in smaller lots, logistics providers may be managing multiple company’s worth of goods in a single warehouse. Ensuring that a contracted company’s goods are handled according to that company’s standards throughout the entire shipping, storage, and distribution process is vital.

Food, Beverage, and Produce

Food storage is a special case because most food and beverage goods are perishable and require a specific environment for storage or distribution. Warehouse management for this industry involves the same elements, namely timetables and temperatures.

Let’s say there’s a major producer and distributor of frozen chicken products. Those products need to be kept at a specific temperature, and they have a set shelf life before they rot and eat into the bottom line as wasted product.

Food is an equally important part of some major warehouse big-box stores, like Costco and Sam’s Club, because people prefer to buy food in person rather than online. Maintaining food inventory across a range of regional stores, both in a warehouse and in-store, is complex beyond manual inventory tracking, hence the value of a WMS.

Retail

Retail warehouse management can be split into two areas:

- Major warehouse management, where the majority of storage and distribution takes place for big brands like Best Buy or other brick and mortar stores

- In-house warehouse management, where a network of individual stores maintain stock for each store or a major region composed of several stores

In both cases, the major challenge facing warehouse management is keeping track of an entire brand’s stock and the location of each piece to avoid things like inventory distortion. Inventory distortion, the total sum of factors like inventory shrinkage, overstocking, or incorrect inventory stock counts, accounted for almost $1.1 trillion lost back in 2015.

Whether trying to keep an accurate count of an item in a brand’s entire system, or looking for a specific item that might be sitting in the back of a store somewhere in south Texas, the tools provided by a WMS create opportunities for warehouse managers to limit incorrect counts or lost inventory.

To that end, asset management and preservation can contribute significantly to a company’s total net revenue from their stock of products, even at the individual store warehouse level.

Manufacturing

The manufacturing industry has a complex warehouse system because it usually handles a wide range of goods. Between raw materials, pre-fab components, and finished products, many manufacturers are responsible for managing warehouses that combine all of those elements.

After all, if you have to bring in all the necessary components to produce a specific product, you will also have to manage and organize those components before they go through the manufacturing and production process.

Let’s say you want to track the lifecycle of a given good as it moves through the manufacturing process. A WMS helps you manage several stocks at different stages of production. You can have a dashboard or list that provides accurate counts of incoming components, follow the components throughout the fabrication process, and finalize finished product counts.

In terms of warehouse management, the WMS helps you ensure that you’re ordering the right amount of materials, maximizing the usage of your manufacturing and warehouse space, and producing an optimal amount based on the previous two factors.

Healthcare

Similar to the food and beverage industry, but on a smaller scale, medical warehouse management presents a complex problem. Compared to the retail or wholesale industries, healthcare certainly demands less volume and storage space, but the severity of quality control and stock management is arguably far more intense.

Primarily, the healthcare industry deals with the storage, maintenance, and logistics surrounding sensitive materials like medication. In some cases, you have specific storage and shipping requirements, like the temperature thresholds for certain Covid vaccines. In other cases, it’s more of a security and harsh stock count issue, as is the case with narcotics and other drugs.

Either way, a WMS can help medical warehouse or stock managers maintain a more complete and accurate overview of medications or medical equipment. Given the cost associated with drugs and medical equipment, spotless item tracking and record generation is a must. There’s a pretty big difference between losing a pallet of TVs and losing a shipment of cancer drugs.

What features should I look for in a WMS?

Finding the right features in a WMS is more about figuring out which problems you need to solve in your warehouse. Warehouse management systems are often designed with a range of applications in mind, including product management and warehouse design.

If you’re looking for a wholistic application, here are some of the core features you should keep an eye out for:

- Warehouse Layout: Organizing the warehouse around the most logical storage and inventory processing layout is one of the best use cases for a WMS. Improved structural organization allows workers and warehouse managers to fully optimize the usage of space to increase capacity and workflow.

- Inventory Tracking: Most WMS have tools that allow you to track inventory as it moves through all stages of shipping and warehouse handling. This might come in the form of a dashboard or generated catalog which provides information like product count, location, and status for everything coming through the warehouse.

- Intake Management: Beyond simply keeping track of your inventory, intake tracking creates a zoomed-out view of how products and stock are entering your warehouse. This is often one of the most important stages of warehouse management, because it’s tied to the actual inventory counts and leads into where products end up in your warehouse.

- Picking and Distribution: A WMS can also help you organize warehouse stock on an individual product or pallet level. By generating accurate location logs and organizing stock by account, product, or location, it’s possible to speed up the process of packaging or distributing inventory.

- Shipping Management: Inventory errors usually happen when inventory is coming in or going out, so managing shipping protocol with accurate warehouse management tools is vital. A WMS should have tools that help you track product shipping schedules for both incoming and outgoing goods.

- Records and Reporting: One of the most important features for any WMS is strong records and reporting generation. Digital lists where you can browse and categorize inventory reports are a major benefit as you reach higher and higher product volume.

Remember to look for general features and integrated options

Beyond features that address specific issues, it’s important to consider how a WMS fits into your warehouse environment. In this case, we mean specific features that work with your equipment and technology. For example:

- RFID scanners and barcode compatibility

- Cloud-based integration options

- Billing and invoice management

- ERP integration capabilities

Essentially, it’s rare that a warehouse or your WMS will serve as a standalone solution. Most businesses either own and operate warehouses or work together with a variety of other businesses that use their warehouses.

You want a warehouse management system that makes it easy to interface with the rest of your business or the ones you work with.

Executive summary

Warehouse management systems help floor managers organize warehouses and stock more efficiently. It’s more than just stacking boxes better, a complete warehouse management system helps you more efficiently manage the flow of products in and out of your warehouse and the product life cycle.

A WMS helps you:

- Avoid losing money to shrinkage, delays, or inventory mismanagement

- Speed up shipping and storage processes

- Maximize inventory-based revenue

- Increase warehouse operations efficiency

The larger your warehouse inventory gets, or as you add warehouses and shipping routes to your network, the greater value you get from a seamless warehouse operation.

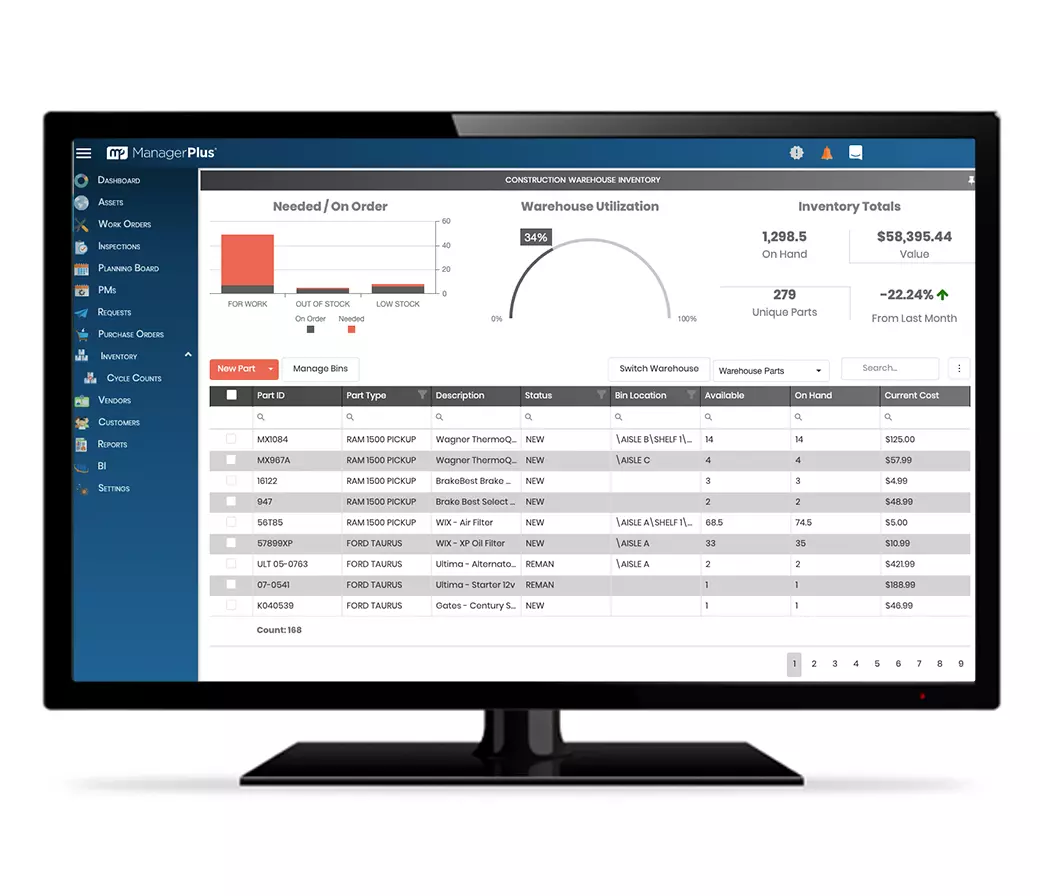

With a wide range of custom features and options and the ability to integrate into existing EAM software, ManagerPlus helps you more efficiently manage inventory, warehouse space or layout, shipping, and more.

Next steps

Getting started with ManagerPlus is easier than you might think. Reach out to our experts to schedule a personalized, one-on-one demo of the software where you can ask questions and see firsthand how it can help take control of your warehouse management.