When you don’t have your warehouse logistics under control, you end up with missed shipments, damaged products, and lost profits.

How can you avoid these extra headaches?

Building an efficient warehouse operation comes down how good you are at keeping data safe, secure, accurate, and accessible. It all comes down to warehouse logistics.

What is warehouse logistics?

Warehouse logistics includes everything connected to the parts, products, materials, and supplies in your warehouse. That includes the people, processes, programs, technology, and anything else that’s a part of moving items around your warehouse. Everything from receiving to stocking to shipping is a part of warehouse logistics.

Operating a warehouse efficiently also involves large amounts of data, which you can consider a part of your warehouse logistics, along with your warehouse management and inventory management software.

Logistics by itself is essentially the detailed planning, organization, management, and implementation of complex operations to accomplish a task. Logistics can be applied to almost any operation within your organization.

What’s the difference between warehousing and logistics?

While warehousing and logistics are similar and share many aspects, they are different. Warehousing refers specifically to the movement and storage of goods within your warehouse facilities. Logistics deals more with your larger supply chain and how the goods get to and from your warehouse, even going as far out as the sourcing of the original raw materials to make the parts that go into the products in your warehouse.

What are the 3 main activities of logistics systems?

Logistics systems are defined by three main activities:

- Order processing

- Inventory management

- Freight transportation

Order processing

Order processing refers to the flow of data through your operations regarding customer orders. While every processing system is different, they typically follow a familiar pattern: customers request products through your ordering system, then the order is checked and verified, the availability of the item is confirmed, the payment method is processed, the items are pulled from stock, packaged, shipped, and the customer is notified.

Unsurprisingly, attempting to manage this process with paper and spreadsheets is time-consuming and prone to error. Barcode scanning as part of a robust, cloud-based inventory management system helps streamline this process and remove the potential for human error by automating most of the steps.

Typically, warehouse workers take on more of a supervisory role in warehouses with this technology in place as they act as a check to confirm things are correct, including pulling the right product, and step in if there are any problems. This means your workers can operate much more efficiently and process a significantly higher number of orders.

Inventory management

Inventory is the key to all warehouse operations; without your inventory, you don’t have products to ship to your customers. Inventory refers to all the physical goods in your warehouse waiting to be manufactured, transported to another location, or sold.

Properly managing your inventory is vital to the success of your operations. Whether you’re a manufacturer of end products or a warehouse company responsible for storing and transporting goods, inaccurate inventory counts can be expensive and potentially devastating to your business if they result in missed shipments or upset customers.

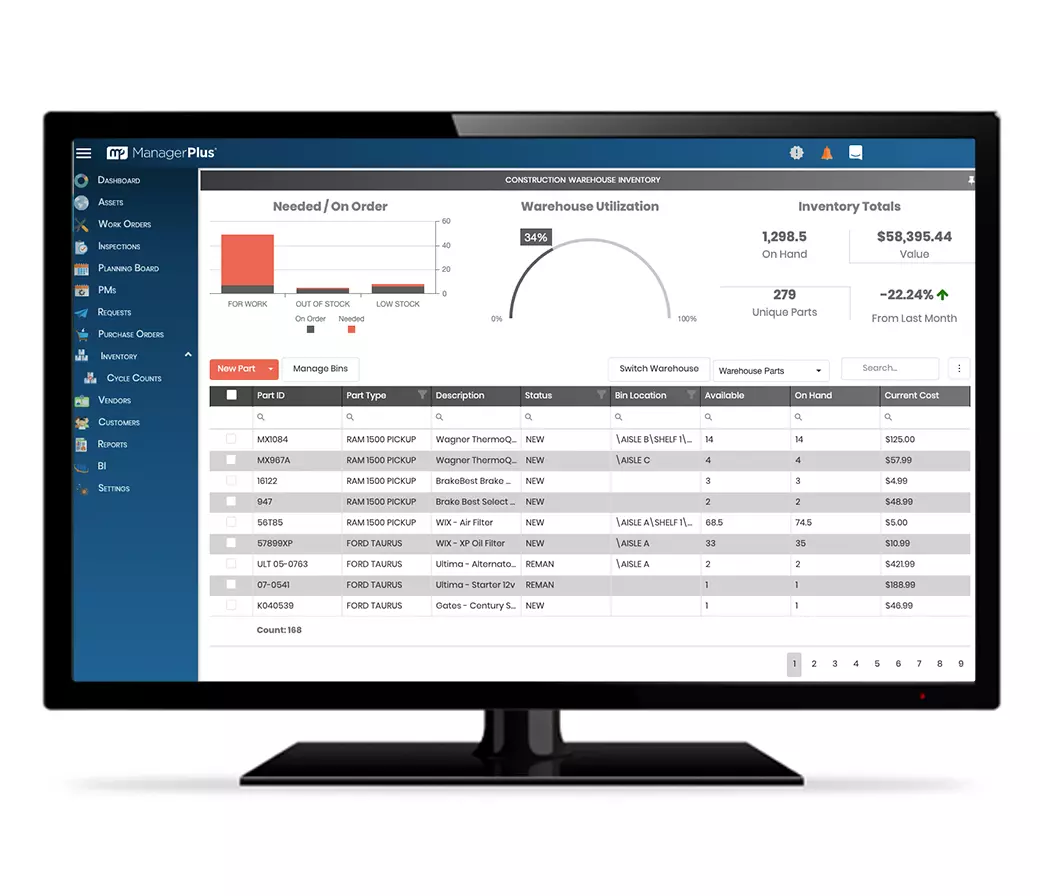

Inventory management is the process of balancing optimal stock levels with the lowest possible cost, all while ensuring customer orders are delivered on time. Inventory management software helps you ensure all of this by gathering data on your inventory levels in real-time and automatically informing you before you run out of products, with plenty of lead time to make sure you receive more in before they’re needed.

Freight transportation

The last main activity of logistics systems is the physical transportation of your items to their intended destination. Transportation of your items is one of the most important parts of your logistical operations and can have a significant impact on your customer service and your business reputation.

Ensuring the correct items arrive undamaged, on time, and at the right location is vital to the success of your business. If you operate your own fleet of vehicles, you can use fleet management software to track your deliveries and maintain your vehicles more efficiently which reduces maintenance costs and extends their life cycle.

What are the common challenges of warehouse logistics?

Operating an efficient warehouse involves quite a few complex moving parts, hence why logistics and warehousing are inevitably deeply intertwined. No matter what types of products you house and ship from your warehouse, there are several challenges that are common across the industry:

- Locating items

- Handling damaged items

- Inefficient processes

- Miscommunication

- Accurate inventory data

Losing track of items

With all the items traveling through your warehouse, it can be easy for one or two to slip through the cracks sometimes. This can lead to a range of problems from not being able to fulfill an order due to inaccurate inventory, or if you work in the food industry, needing to track down the exact path an expired food item took through your building.

The ability to accurately track every step an item took through your operations is vital to the success of your business and helps you avoid costly fines, damages to your reputation, and even expensive litigation.

Dealing with damaged items

Damaged items are a part of the warehouse industry, but they can often go unnoticed without proper logistics operations in place. If a damaged item is counted among your sellable inventory, your entire product count will be inaccurate, and it will directly impact profits. Not to mention that it’s also taking up space where a good, sellable item could be stored.

You need to be able to quickly identify damaged or unusable items and quickly dispose of them or remove them from your warehouse.

Clumsy, outdated workflows

As every warehouse manager knows, there are endless processes and workflows involved in your operations, but each step is also vitally important for ensuring things run smoothly. The problems arise when trying to manage these processes and workflows with outdated solutions.

If your team is still having to do everything by hand with paper or spreadsheets, they’re wasting valuable time they could be using to receive, sort, package, and ship additional products that could directly increase your profits.

With the right technology and software working together, you can automate many of the tedious, time-consuming processes you’re currently wasting money on and free up your team to get more done.

Miscommunication

Your teams and your technology need to be able to communicate effectively in order to do their jobs. When it’s time to pick an order, your workers need to know exactly where the item is and how many are available, so they don’t waste time running back and forth across the warehouse looking for something.

Good communication is also vital regarding your customers. Make sure to keep in touch with them as much as possible throughout the process so they know what’s going on, especially if there’s a problem. Most customers are willing to forgive mistakes and things out of your control, as long as they know what’s going on.

Inaccurate, out of date inventory data

Robust warehouse logistics operations thrive on good data but often inventory and warehouse data are not updated or entirely accurate. Implementing cloud-based warehouse management software helps eliminate this problem by keeping your team always connected and all your data accurate. Any changes to your information are reflected instantly in the program so everyone is always working from the same, accurate source of data.

What are the benefits of warehouse logistics?

Ultimately, the goal of any business is to increase revenue—if your company isn’t aiming to increase revenue, it won’t be in business long. Efficient, robust warehouse logistics go a long way toward meeting that goal by improving many of the critical details.

Well-managed warehouse logistics help you ensure accurate, real-time inventory counts so you always know what inventory you have, where you have it, and get it to the right place at the right time. This, in turn, helps decrease your returns because more of your customers get the right product the first time. And it makes it easier to track down where the problem occurred if there is an issue.

Even a short stock out can be disruptive to your operations. Warehouse logistics helps you keep the right amount of inventory on hand, so you never run out. With inventory management software, you can set min and max par levels and get automatically notified when it’s time to order more.

When you have everything in the right place and are efficiently managing your operations so you know where everything is, where it’s going, and how much of it you need, you can begin to optimize the space in your warehouse to maximize value. As your company grows and evolves, you are better prepared to adapt and continue to realize maximum value from your warehouse.

How can you improve warehouse logistics?

The best and quickest way to improve your warehouse logistics is to adopt technology that can automate tasks and streamline your processes. Warehouse management software is designed to do just that by gathering data in real-time across your operations and helping you eliminate gaps and inefficiencies.

For example, the moment inventory is received, your team can scan it with barcode scanners so your database instantly adds the right SKU number, amount, and any other relevant information so your order processing system can open up room for new orders to customers.

Ultimately, warehouse logistics are not a one-and-done situation. Once you improve your processes, your need to continually monitor them to look for areas to improve. Warehouse management software can help you do that too. The best solutions help you generate customized reports based on the KPIs you want to track so you can quickly see where you need to improve.

Next steps

To get started improving your warehouse logistics, reach out to our experts to schedule a personalized one-on-one demo of our warehouse and inventory management software so you can see firsthand how it can help you streamline your operations.

Executive summary

Warehouse logistics, order processing, inventory management, and freight transportation, are vital to the success of your business. Inefficient warehouse logistics can lead to a range of problems for your organization, including missed shipments, lost inventory, increased costs, and even potential litigation and compliance fines.

Well-managed warehouse logistics help you:

- Ensure accurate, real-time inventory data

- Avoid stock-outs

- Optimize warehouse space

The best and quickest way to improve your warehouse logistics is by adopting warehouse and inventory management software.