Heavy equipment is a must-have for most construction sites. And equipment management software is the best way to maintain your equipment and keep every safe while on the job site.Improperly maintained equipment can not only be dangerous, but it can also lead to costly repairs and equipment failures down the road.

Let’s look at the most common types of earth-moving equipment and some tips and best practices to keep them safe, well maintained, and running efficiently.

What is earth-moving equipment?

As the name might suggest, earth-moving equipment generally refers to any piece of heavy machinery that can move and grade soil and rock. In addition to construction work, they are also used for materials handling, demolition, mining, and any other industry that requires more power than can be provided by humans.

Types of earth-moving equipment

There are many different types of earth-moving equipment that each have their own uses and are designed for specific purposes.

The most common types of earth-moving equipment are:

- Excavators

- Backhoes

- Bulldozers

- Dump trucks

Excavators

Excavators are one of the most efficient digging machines ever created. They are most commonly drive by tracks but can have wheels fitted to them if necessary. Their long arm and large bucket make them ideal for almost any situation. The operator sits in a rotating cab that can swing a full 360 degrees allowing him good visibility of the job site. Depending on the situation, the bucket can be swapped out with a variety of other tools to fit the needs of the job.

Backhoe loader

More commonly referred to as a backhoe, backhoe loaders are more versatile than excavators but are considered medium-sized equipment. They are smaller and look more like a typical farm tractor with an adjustable shovel in the front and a bucket in the back for more precise digging. They are wheel-driven and can maneuver more precisely and are often used in urban areas.

Bulldozers

Bulldozers are some of the most powerful equipment used in the construction industry and are used to move and grade dirt across large tracts of land. They have a large blade in the front that can make small adjustments to its height and angle depending on the task at hand. They are extremely large and heavy and their size and weight can be used to crush boulders if needed.

Dump trucks

It’s almost impossible to see a construction site without a dump truck. They are really only designed for one purpose: to move large amounts of dirt from one site to another. They are designed to be able to travel on roadways where permitted and come in a variety of sizes and load capacities to meet the needs of the job.

Earth-moving equipment maintenance best practices

Earth-moving equipment is expensive and complex—which makes proper equipment maintenance essential.

Equipment and tools that function correctly have a lower chance of causing injuries or deaths. This is especially important since thousands of workers are injured annually by earth-moving equipment. Machine-related injuries were among the top ten OSHA violations in 2019, while 20% of work fatalities (1,061 deaths) occurred on construction sites that same year. These seven best practices will help keep your employees safe and extend the useful life of your earth-moving equipment.

1. Clean your earth-moving machinery

A great way to keep earth moving equipment safe is to clean it thoroughly. This type of equipment has to do difficult and dirty work, which can alter the performance of the machine. Because of this, earth-moving machinery and all its parts should be cleaned regularly.

Dirt, grime, and debris will start to accumulate on and in parts of the equipment. These parts and tools become damaged, malfunction, or stop working eventually if you don’t clean them properly. It’s important to only clean heavy machines with solutions that the manufacturer recommends. This helps avoid damaging delicate parts with harsh chemicals.

2. Train employees to operate earth-moving equipment

Your earth-moving machinery’s parts and tools are in danger of becoming damaged or completely broken if an untrained worker attempts to operate them. The worker is in danger of becoming injured or hurting others.

To protect your employees and equipment, all workers need to be properly trained to operate earth-moving equipment. No one should operate heavy machinery without adequate training and qualifications. Training teaches workers the limits a specific piece of heavy machinery may have, how to use the right tools for the job, take proper safety measures, and follow operating guidelines.

In addition, have a qualified employee look at the area where you’re going to use the equipment, and let them do a risk assessment. They can take a careful look at the machinery and the environment to make sure it’s safe and meets all requirements before operating. In most construction and mining sites, having a skilled worker that supervises the operation of heavy machinery is vital. This person should have the training and experience necessary to make sure the operator and anyone in the immediate area stay safe.

3. Lubricate your equipment carefully

Heavy earth-moving equipment and associated parts and tools will malfunction or become damaged if they aren’t lubricated properly. Moving parts and components need lubrication because the frequent movement causes friction. This friction can severely damage the parts and tools of earth-moving machinery.

To keep them safe, lubricate every joint as well as all other areas that require lubrication. Do this regularly, but be careful never to use too much, as excess lubrication can cause grease build-up and other problems.

4. Take steps to avoid injuries

Teach construction workers to spot any potentially dangerous problems and how to handle any situations that might occur. For example, if they have to drive up or down a steep hill, they must know how to select the proper gear.

They also need to know what angle to drive at because they could topple over if they make a mistake. This can result in life-threatening injuries.

That’s why it’s so important to teach your crew how to avoid falling off earth moving equipment. Place durable guardrails on your earth-moving machinery. Employees also need to repair earth-moving equipment while standing on the ground whenever possible for safety.

Workers who aren’t operating heavy machinery should maintain a safe distance from it while it is moving. Also, be sure all heavy equipment is parked in a safe area. Place cones around it to protect your employees and the equipment.

5. Maintain earth moving equipment properly

Heavy machinery and tools that aren’t properly maintained can be dangerous to operate. Improper maintenance can cause the tools and other parts to become damaged and unsafe as a result. Small problems that aren’t repaired may eventually become massive issues that require entire sections to be replaced.

This is why it’s so important to have a plan for preventive maintenance.

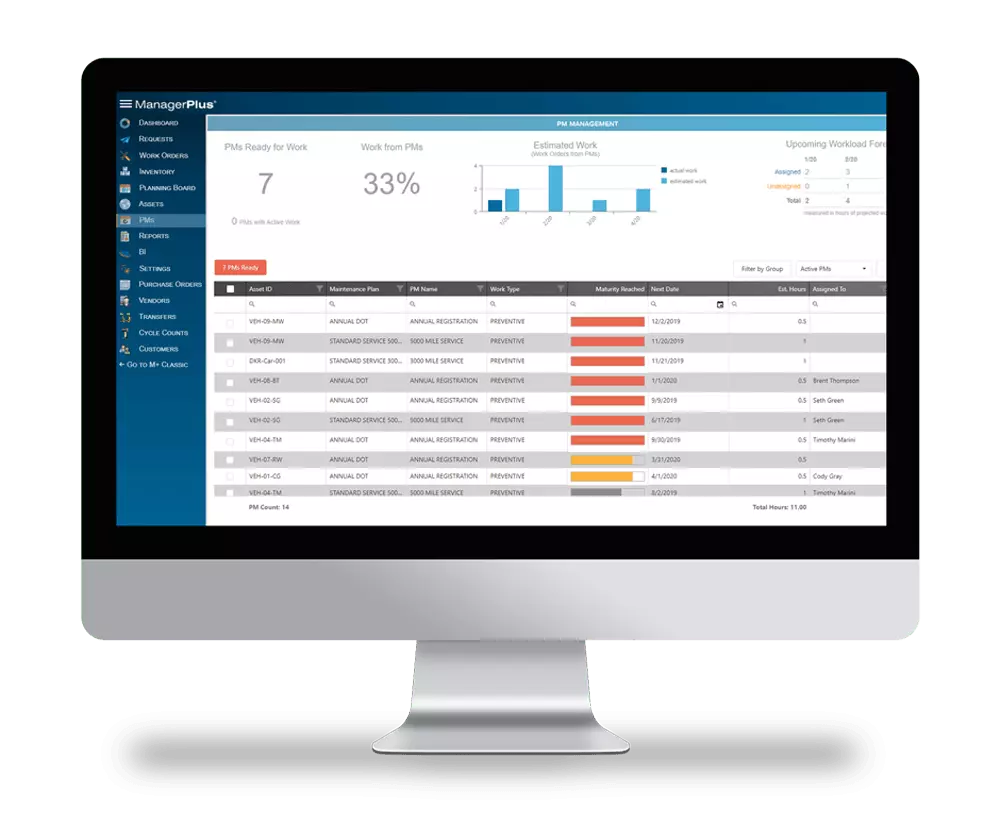

Using equipment management software, you can schedule many PM tasks in advance and send automated notifications to your maintenance technicians when it’s time to perform them.

Based on the manufacturer’s guidelines, you can schedule these activities by date or by usage.

Based on the manufacturer’s guidelines, you can schedule these activities by date or by usage.

With some parts, such as tires, you need to replace them after a certain amount of mileage. With other parts, you need to replace them according to time intervals.

6. Inspect earth moving equipment regularly

Regular equipment inspections go hand-in-hand with preventive maintenance.

Your inspection schedules may vary depending on the types of earth-moving equipment you have and how often you use it, but it’s a good idea to conduct these inspections at least once a year. If you don’t have an in-house mechanic, consider hiring someone to inspect your equipment.

Make sure they document their findings using a mobile app or a software platform.

That way, you can maintain equipment inspection records from one year to the next, no matter who inspects your equipment the following year.

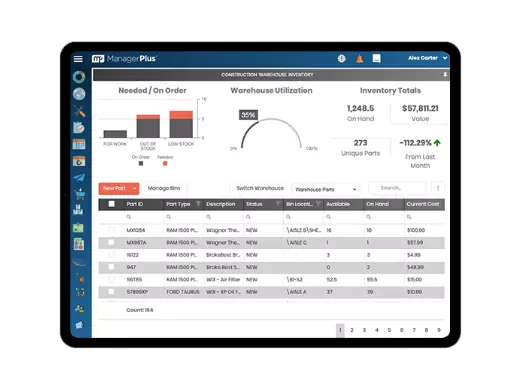

You also have a record of any parts you repaired or replaced and the costs.

7. Use the right parts and tools

You shouldn’t try to attach tools to heavy machinery and use them if they won’t fit or aren’t compatible. If you attempt to do this, you are putting the machinery at risk. Employees are also at risk. Read through the manufacturer’s manuals, and find the right parts and tools.

Also, when your machinery is going to be used to do a certain job, check to see what kind of tool is best. By selecting the right tool, you’ll do the job more efficiently, and you’ll keep the equipment, operator, and tools safe.

Track inspections and maintenance with equipment management software

Earth-moving equipment requires proper maintenance, repairs, and regular cleaning by experienced technicians.

It can be difficult to keep track of a program with this many moving parts without a structured system in place. Equipment management software makes it easy to schedule and document preventive maintenance activities, record inspection details, and see which parts you have on hand and which you need to order.

And having a mobile app makes it easy for anyone to use the software from any location, whether they are contractors, operators, or maintenance technicians.

Next steps

If you’re ready to see how equipment management software can help you better maintain your heavy equipment, you can schedule a live, personalized, one-on-one demo of our ManagerPlus software so you can see firsthand how easy it is to use our solution.

If you already know your organization needs a solution like this but some of the decision-makers still need some convincing, the section below is a short summary of this article that you can copy and paste into a quick email to them so they can make an informed decision.

To learn more about when to inspect different types of construction equipment, download this handy checklist, The ABCs of Construction Equipment Maintenance.

Executive summary

Earth-moving equipment is essential to almost any construction site but improperly maintained equipment can be expensive and dangerous. It’s vital that you take regular steps to clean and maintain your heavy equipment to keep everyone safe and avoid expensive equipment failures.

The best way to ensure your equipment runs as expected is with equipment management software. ManagerPlus is a complete enterprise asset management (EAM) solution that helps you implement and track a preventive maintenance program, record inspections, and manage inventory to keep costs down.

ManagerPlus is cloud-based and the mobile apps allow your team to take the software anywhere and always have up-to-date information on all your earth-moving equipment and assets.

This post was originally written by Barton Henderson, manager at Statewide Bearings, distributors of bearings, and other parts for earth-moving machinery, with branches across Australia. It has been updated with more recent information.