As a fleet manager, one of your main priorities is to avoid vehicle breakdowns. Every minute your vehicles are off the road is money your company is losing.

You need to keep your vehicles up and running for as long as possible, and when they do need maintenance, you can’t afford any delays or mistakes in the repair process.

Developing a strong preventive maintenance strategy as part of your fleet maintenance management program can help you repair your assets before they break down, keeping them, and your drivers, on the road longer.

Whether you manage pickup trucks, garbage trucks, or semis, this checklist is good to keep in mind as you build out your preventive maintenance plan.

What is fleet maintenance management?

Fleet maintenance management basically refers to anything involved in keeping your fleet on the road and running smoothly. This includes everything from performing inspections to conducting preventive maintenance on your vehicles.

As part of your fleet maintenance management program, you want to be able to:

- Track critical data on your vehicles in real time

- Perform inspections and store records

- Identify potential maintenance problems

- Schedule preventive maintenance work to avoid vehicle downtime

- Track parts inventory

- Track maintenance work orders

You are probably already doing most of this in some form or fashion, but many commercial fleet carriers either use outdated methods of handling their information such as paper or spreadsheets or their data is spread out across multiple systems and databases.

Why do you need fleet maintenance management?

With so many things to keep track of, you need one, unified, always-connected solution so you have access to all your critical data whenever you need it. You need a solution with robust mobile apps so your drivers can perform their inspections on the road wherever they are, and you can keep track of your vehicles’ maintenance from anywhere.

1. Get more road time out of your vehicles

This one might seem a bit obvious, but the most immediate and most noticeable benefit from implementing a fleet maintenance program is that you can keep your vehicles on the road longer. With a strong preventive maintenance program in place, you can repair your vehicles before they break, which means less downtime, more drive time, and less maintenance costs. Win-win-win.

2. Lower maintenance costs

When you wait until an asset breaks before you repair it, not only do you rack up costs in parts and labor, you’re also losing money due to unscheduled downtime. If you maintain your assets properly with a strong preventive maintenance program, you can avoid costly reactive maintenance, extending the life cycles of your assets.

With a preventive maintenance program backed up by a robust enterprise asset management (EAM) solution, you can keep track of ever dollar you spend on vehicle maintenance. Once you know where your money is going, you can make informed decisions on where to spend your money.

3. Boost company profits

The biggest benefit of having strong fleet maintenance management is the positive impact it has on your company’s bottom line. More road time for your vehicles means more deliveries made on time. More on-time deliveries mean your drivers are available faster to pick up new deliveries.

You can keep your customers happy and build a stronger reputation as a carrier when you’re not having to deal with unexpected breakdowns on your trucks.

How to implement a preventive maintenance program

Now that you know why you need a preventive maintenance program for your fleet, let’s look at how you can get yours up and running.

1. What you need

There’s several things you’ll need to establish within your organization to ensure your preventive maintenance program runs smoothly:

- A comprehensive list of preventive maintenance work that needs to be performed on your assets

- How often certain maintenance activities need to be performed

- A process for drivers to submit inspections

- An automated system for keeping track of your vehicles, inspections, parts, technicians, and work orders

2. Gather current and historical vehicle data

Before you can know when you need to repair your vehicles, you need to know the current state they are in. Any piece of information you have about your vehicle’s maintenance history is important.

Once that data is loaded into your EAM platform, you have a comprehensive picture of the status of your vehicles and what required repairs. You might even find some maintenance gaps you didn’t know where there.

3. Determine maintenance intervals

Preventive maintenance involves replacing parts on your vehicles before they completely wear out and cause further damage. Reactive maintenance involves waiting until a certain part fails before you replace it. There are certainly use cases for both, especially on vehicles, but to use preventive maintenance effectively, you need to establish the intervals at which certain activities should occur.

An easy example is changing the oil. It should happen every few thousand miles either depending upon your technician’s experience with the vehicles and when they need the oil changed or based on the manufacturer’s recommendations.

Every vehicle is different, however, and if you have multiple types of vehicles, they all might need different maintenance schedules. These will be tuned and refined better as you take advantage of your EAM solution, but as long as you have a general idea, you can get quickly started with your preventive maintenance program.

4. Develop a maintenance checklist

Your technicians already have a good idea of what maintenance they need to perform on your assets, but you can always consult the manufacturer or industry standards to give you an idea.

Some of the high level areas of your vehicles that should certainly be on your list are:

- Engines and fuel systems

- Cabin controls (uncomfortable drivers are distracted drivers)

- Safety features

- Lights

- Undercarriage

- Fluid levels

- Tires and tire pressure

- Belts

Your technicians can develop much more in-depth lists for each category, but those are some of the main areas you should regularly be checking.

5. Develop inspection and reporting procedures

Regular inspections are vital to keeping your vehicles running. You can’t replace parts before they break, if you don’t know which parts are nearing the end of their useful life.

Your drivers need an easy, reliable way to perform their driver’s vehicle inspection reports (DVIRs) while on the road without having to fumble around with paper or spreadsheets.

If you have smaller trucks or vehicles, your operators need to be able to quickly inspect their vehicles and request any maintenance work to be done.

You need all your inspection reports stored in one easily accessible database so you can pull them up right when you need them, especially during compliance audits.

A good fleet management software platform can store your DVIRs and other inspection reports in a cloud-based solution that you can access anywhere, any time.

ManagerPlus Lightning offers mobile apps for both operators and technicians. The Operator Companion app allows operators to inspect their vehicles, mark them as simply pass or fail, and request maintenance work right from the app. The Work Companion app for technicians enables them to quickly scan a bar code on the vehicle and instantly pull up any open work orders for the vehicle along with any other necessary information they need to get it repaired and back on the road quickly.

6. Track metrics and evaluate performance

One of the main benefits of a good preventive maintenance program is it allows you to track key performance indicators (KPIs) for your vehicles so you can evaluate how well assets are working for you. If a certain vehicle is costing you more and more each month to maintain it, it might be cheaper to just replace it.

A good EAM software can help

Keeping track of all your vehicles is a difficult task. You need a fleet management software that works as hard as you do. With good fleet maintenance management software, a lot of the work is done for you. Automating your preventive maintenance work orders and keeping track of your vehicles maintenance work allows you to focus more time on making decisions and managing your team effectively.

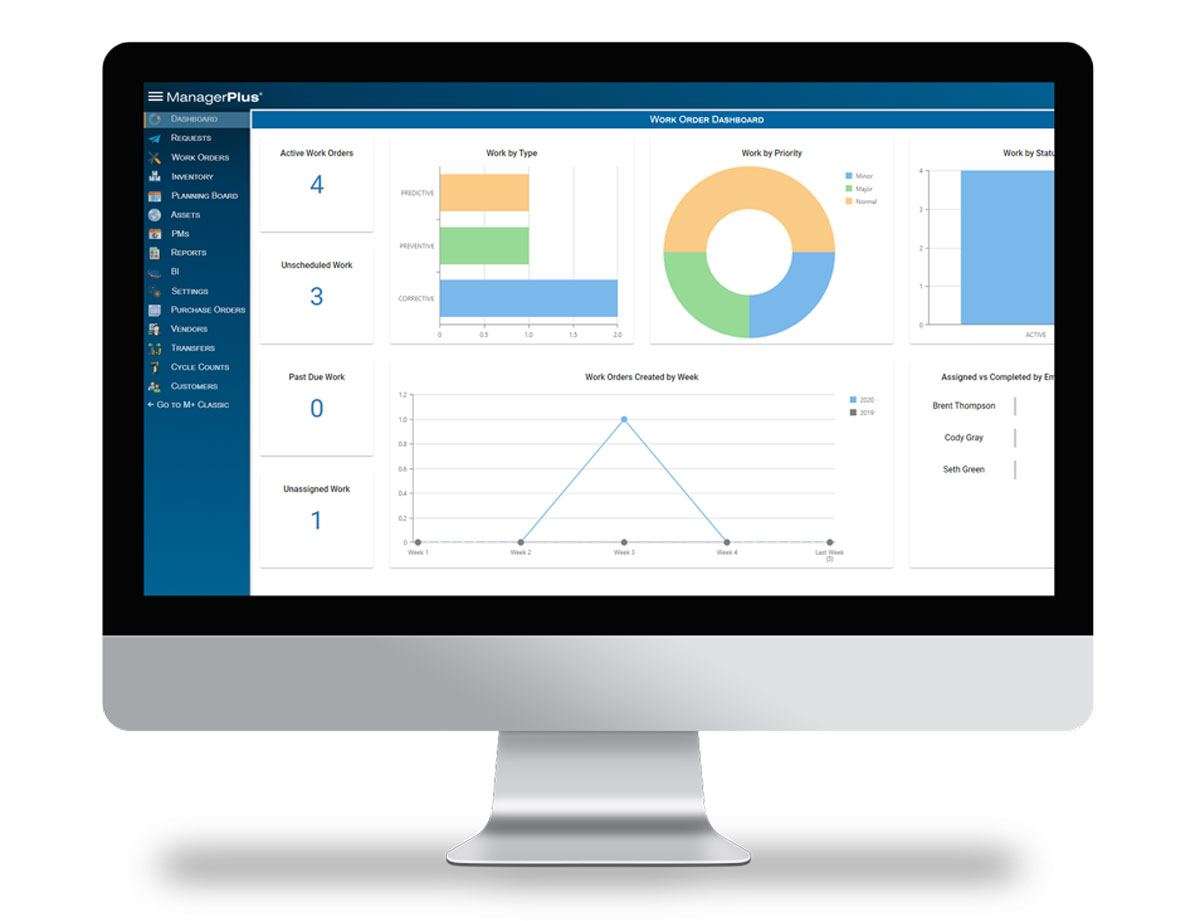

Intuitive dashboard

EAM software collects a lot of data about a lot of different things. A good EAM will distill your information down to the most important data you need to see, right up front. It will make it easy to navigate and modify data as needed to keep track of where everything is.

Intelligent reporting

A preventive maintenance software is only as good as the data it collects and manages for you. If you don’t have accurate, up-to-date information about your assets, you can’t make informed decisions on how to spend your money effectively. Lightning leverages data to generate detailed reports for you on whatever you need, and you can customize them to see just the KPIs you want.

Inventory management

There’s a lot of parts involved in keeping a fleet on the road, everything from fan belts to lightbulbs, and your technicians don’t have to time hunt down parts every time they get a new work order. Cloud-based EAM software can help you keep track of your parts as they get used, and can let you know when it’s time to order more so you’re vehicles are never sitting idle while you wait for parts.

Inspections

If you’re having to rely on your drivers and operators to fill out manual inspection reports, critical maintenance work can easily be missed, not to mention the potential for failing compliance audits.

You need a software platform that makes it easy for your team to input inspection data and makes it easy to track and produce when you need it most.

With Lightning, drivers and operators can quickly perform inspections from their connected device and the records are stored in the cloud so you can access them any time.

Best of all, when a vehicle fails an inspection, Lightning can automatically trigger a work order, so you don’t have to worry about critical maintenance work getting missed.

Vendor management

The Vendor Portal within Lightning allows you to send work orders to third part contractors if you need to bring in some outside help. No more calling or emailing back and forth to hash out the details. The vendor receives a temporary link with access only to the work order they need and any related information, so your internal data stays secure.

The vendor can upload pictures of their work as well as their final invoice so you can take care of it all without ever leaving the software. You can even request a signature if you need one of your technicians to double-check the work for any reason.

Automated work orders

How much time do you spend simply trying to manage your team’s work orders? Lightning can use your pre-determined maintenance intervals and condition-based data it collects from your assets to automatically schedule preventive maintenance work orders. It even assigns them to the technicians you specify, which is extremely useful if you have a few specialized vehicles that need to be worked on by an expert.

You can also build work order templates to make sure that all the information your technicians need is included with every work order. You can include things like user manuals, pictures, and even expert advice. If you’ve got a few guys on the team who know your vehicles inside and out, you can rest easy that their expert knowledge won’t be lost when they move on.

Universal accessibility

By nature, fleets are mobile. You and your team are always on the go, so your EAM software needs to go with you. Lightning is accessible from any Internet browser so you can either manage it from your office desktop, or out in the field on your tablet or laptop.

The mobile applications make the software even more accessible. Your operators and technicians each have their own apps so you can avoid miscommunications and any potential frustrations that might arise between your teams.

Keep your fleet on the road with EAM software

Every second your vehicles sit idle your costs add up. A robust preventive maintenance program can both cut your costs and get you more out of your assets. But a preventive maintenance strategy is only effectively if it’s implemented and managed properly.

Lightning can help you get up and running and give you the tools you need to optimize and improve a program over time.

Schedule a demo with us today to get started implementing a preventive maintenance program.