Every second counts in manufacturing and production, where even the smallest disruption in your equipment can cause tens of thousands of dollars in losses.

But how can you know how efficient your equipment really is?

Overall equipment effectiveness (OEE) is best way to fully understand how well your equipment is performing and where there might be gaps you need to fill in your operations.

What is overall equipment effectiveness (OEE)?

In the manufacturing industry, overall equipment effectiveness (OEE) is one of the most important maintenance-related metrics you can track for you company.

OEE provides one of the quickest ways to assess operational efficiency. It can also help you pinpoint performance issues. If a particular machine has a high rate of downtime, you likely have a maintenance issue, a part that needs to be replaced, or operator error. Surprisingly, many companies fail to track this important key performance indicator (KPI).

The basic definition of OEE is the percentage of time your equipment is actually productive and generating revenue for your company.

The three main metrics used to determine and assets OEE are:

- Availability

- Performance

- Quality

Availability refers to how often the asset performs as needed. Essentially, the uptime. This includes both planned and unplanned downtime. An asset with 100% availability means that it is always running during planned production times.

Performance tells you how quickly the equipment is producing products. It is a function of how many units are produced compared to the idea cycle time. 100% performance means that the equipment is producing as quickly as possible, with no slowdowns or minor stoppages.

Quality is simply the number of good manufactured parts the asset produces in the established time period. An asset with 100% quality produces no defective parts.

Effectiveness vs. efficiency

It’s easy to get these two terms confused or to assume they’re interchangeable in regards to OEE. They’re not.

An equipment’s effectiveness refers to the relationship between what is actually produced during a production period versus what could potentially be produced. Basically, if your machine can produce 1000 units per hour but it only actually produces 800, then it is only 80% effective.

This does not mean the machine is 80% efficient, however. Effectiveness does not take into account other factors involved in operating the equipment. The number of operators, energy, materials required, and several other things could all contribute to a machine’s efficiency.

How to calculate overall equipment effectiveness

There are two formulas you can use to calculate OEE, the Simple Calculation and the Preferred Calculation.

The Simple Calculation will quickly give you a broad overview of the OEE for your asset. This is found by multiplying the number of good parts produced with the ideal cycle time, then divide that number by the planned production time.

This is good formula for getting a very basic overview of your equipment’s effectiveness, but it doesn’t really tell you how you can improve you operations because it doesn’t take into account the factors that might be contributing to your losses (availability, performance, and quality).

For that, we need the Preferred Calculation.

The Preferred Calculation takes all three more granular metrics of availability, performance, and quality, also known as loss factors, and multiplies them together to get overall equipment effectiveness.

Let’s look at how we find these three metrics so we can calculate a much more accurate OEE, and how enterprise asset management (EAM) software can help us track and improve these metrics.

How to improve OEE score

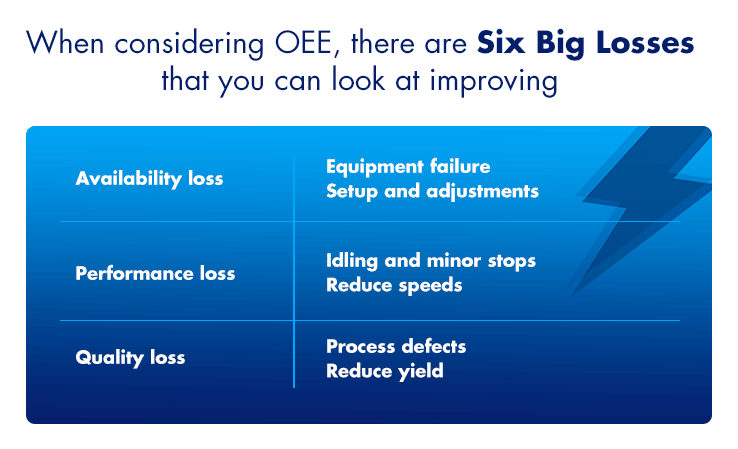

The reason we prefer to use these three metrics to calculate overall equipment effectiveness is that they can also show where a company is experiencing losses and how they can optimize and improve production.

Equipment failure

Downtime is a part of any production system but unplanned downtime is a huge burden that can incur significant costs, not to mention bring down your OEE score. Unscheduled downtime can be significantly reduced and sometimes even eliminated with a strong preventive maintenance program. With ManagerPlus Lighting, you can also track your historical equipment downtime to spot any trends and gain even more insight into how to optimize production.

Setup and adjustments

Planned downtime due to setups or adjustments needed for equipment is important and beneficial to production. While it is a normal part of any production operation, there’s a good chance it could be optimized more than it is currently. The gold standard for equipment changeovers or adjustments is less than 10 minutes.

Idling and minor stops

Minor stops are typically any equipment stoppages that last less than five minutes. Be careful though because these little stoppages can add up to a significant amount of time over the course of a shift. By keeping an eye on the scope and nature of these adjustments over time, you can spot inefficiencies or potentially larger problems.

One way to avoid potential minor stops with your equipment is to have your operators inspect it regularly and immediately report issues to maintenance. With ManagePlus Lightning, operators can inspect and either pass or fail their equipment right from their connected devices so inspections can happen quickly, and maintenance can be automatically notified as soon as an issue is spotted.

Reduced speed

This is when your is operating at slower speeds than its Ideal Cycle Time. This typically happens when equipment is poorly maintained or even due to wear and tear. Ensuring each of your critical assets has a regular preventive maintenance schedule set up for it and reviewing maintenance tasks for them helps you ensure they are operating as close to their Ideal Cycle Time as possible.

Process defects

Rejected units will happen during production but if you are continually monitoring and maintaining your equipment, you can keep these to a minimum. Increased monitoring and evaluation will be important as your equipment ages or as new team members are brought on board. Operator errors are a common cause of defects.

Reduced yield

Reduced yield refers to defective parts that are made between equipment startup and stable production. This typically occurs after changeovers, during warmups, or due to incorrect settings on your equipment.

How EAM software improves overall equipment effectiveness

World-class companies define several specific timespans (work shifts, for instance) and calculate the overall equipment measures for each to compare them.

Here’s a closer look at how to calculate each one using EAM software.

How EAM software improves equipment availability

Availability is the foundation for calculating overall equipment effectiveness because it is a straightforward measure of downtime. When it comes to improving OEE, availability is the best place to start.

There are two key factors involved in availability: machine breakdowns and machine adjustments/setups.

EAM software makes it easy to track machine runtime in the form of logs that can be entered via any connected device. In ManagerPlus, the Work Order Down Time report shows the amount of time that a piece of equipment was inoperative.

Let’s say we have a forklift that has been down for 65 days and let’s assume for this example that the total number of days that this forklift should have been available is 365. The runtime would therefore be 65 – 365 or 300 days.

Let’s say we have a forklift that has been down for 65 days and let’s assume for this example that the total number of days that this forklift should have been available is 365. The runtime would therefore be 65 – 365 or 300 days.

Availability = 300/365 or 82%

We’re not too far off from the world-class benchmark range of 90%. Now, how do we get there?

First, we want to look at the asset history for this forklift in our EAM software. If the majority of the work orders associated with it were for reactive repairs, scheduling more preventive maintenance will likely help reduce downtime and push us closer to the 90% range.

In this example, there have been three work orders associated with reactive repairs that have been performed on this forklift—these account for the 65 days that the forklift was inoperative.

If we examine these work orders more closely we might find that the engine has persistent issues. You can pay closer attention to the parts, services, and notes in the work orders to identify common issues.

Based on this information, we can then build preventive maintenance schedules in the system to prevent full-down breakdowns in the future.

Let’s say that we create a preventive maintenance schedule with some routine engine checks and part replacements—performing these tasks will require far less than 65 days and will therefore help boost availability for this asset.

In addition, preventive maintenance software makes it easy to create these PM tasks that can be applied to multiple assets. In this case, you could create a single schedule for all similar forklifts.

By taking a more proactive approach to preventive maintenance, you can reduce breakdowns and spend more time making smaller adjustments.

How EAM improves equipment performance

Ideal Cycle Time, sometimes referred to as Nameplate Capacity, Theoretical Cycle Time, or Design Cycle Time, is a measure of what a given piece of equipment should be capable of producing under ideal circumstances within a given timeframe.

In manufacturing settings, this is usually measured by throughput — how many parts/pieces a machine produces. In other industries, such as construction, this can be somewhat more difficult to measure, but virtually any measure of output/productivity is workable.

Tracking this log type will make it much easier to calculate the performance portion of the OEE equation. Ideal Cycle Time data can either be established manually by tracking cycle counts over time, or obtained through the equipment manufacturer.

With this information in hand, it will be much easier to assess the efficacy of your maintenance program directly in terms of productivity, adding another dimension to basic measures of uptime.

The Log Change Summary report in ManagerPlus provides an easy way to track these values and adjust your maintenance schedules accordingly.

How EAM improves quality

As with equipment performance, quality is easiest to measure in manufacturing settings where you are producing physical products. This doesn’t mean organizations that provide services need to be left out—it just takes some creative thinking to come up with ways to measure the overall quality of the services you provide. Measuring in terms of positive reviews or customer complaints and tying those back to equipment performance are a good start.

Using ManagerPlus EAM software, you can set up a separate cycle count for quality similar to how you set up a cycle count for performance. If you already have a cycle count set up for total output, all you have to do is add another for the number of rejected pieces and you’re all set. Simply subtract the latter from the former and divide the result by the total output.

What are benchmarks for overall equipment effectiveness?

The key with OEE is to bear in mind that all three components—availability, performance, and quality—need to be balanced. If increasing equipment availability leads to a substantial decrease in quality, you don’t have strong overall equipment effectiveness.

While there are world-class benchmarks for overall equipment effectiveness, they have remained unchanged for decades. They are:

Availability: 90.0%

Performance: 95.0%

Quality: 99.9%

OEE: 85%

While these standards reflect the best of the best, they are far from typical. Vorne cites studies indicating the average overall OEE for most manufacturing plants is closer to 60% and companies who are just beginning to evaluate their equipment effectiveness typically start around 40%.

Instead of trying to measure up to these standards and falling short, set realistic goals for key pieces of equipment. If you want to ensure the maximum efficiency of your equipment, you need your own internal benchmark for comparison.

This is the only way you’ll know if you start to veer off course.

What do I need to know?

Overall equipment effectiveness (OEE) is one of the most important maintenance metrics for the manufacturing industry. It is used to assess operational efficiency and pinpoint performance issues.

It’s the percentage of time your equipment is actually productive and generating revenue for your company.

It’s calculated using an equipment’s Availability, Performance, and Quality

Availability x Performance x Quality = OEE

The target OEE percentage is 85%.

To learn more about how ManagerPlus helps you improve overall equipment effectiveness, request a demo today.